Topic: a, b, c, d, e or f

The Second TSME International Conference on Mechanical Engineering

19-21 October, 2011, Krabi

Investigation of Load Profiles of Lithium-ion batteries

for Electric Vehicle Applications

Chadchai Srisurangkul

National Metal and Materials Technology Center, 114 Thailand Science Park, Phahonyothin Rd. Klong 1, Klong Luang,

Pathumthani 12120 Thailand

*Cor esponding Author: Tel: +66 2 564 6500 ext. 4731, Fax: +66 2 564 6332,

E-mail: [email protected]

Abstract

Vehicle electrification become and continues to be the major trend in the automotive industry and

a main part of this is batteries. Unfortunately the battery testing presently does not represent the real-

world condition, in which the bat ery load profile comprises complex charge-discharge wave. Therefore in

this study, the load profile of bat eries for electric vehicles was investigated. An integrated simulation and

testing approach is used to predict the bat ery load. In simulation the bat ery load profile is calculated

based on the utilization of vehicle and battery model. The present vehicle and bat ery model are

developed using a vehicle dynamics technique and equivalent circuit modeling technique respectively,

whereas the model development is focused on a specific vehicle which converts conventional propulsion

into pure electric propulsion. The results are demonstrated through the current profile of advanced

bat eries subjected to standard driving cycles. With this approach, the battery loads correspond to actual

driving condition or any driving cycle can be predicted and can be used for bat ery testing. This creates a

new aspect to evaluate advanced bat eries for power train application.

Keywords: Current Profile, Vehicle Modeling, Bat ery Modeling, Driving Cycle

1. Introduction

some bat ery parameters but still not suite to

All major car manufacturers are planning

investigate, for example, the bat ery life or heat

to bring out electric cars in the near future. This

generation. It is not suitable to use as tool for

trend drives the development of high power

design bat ery subsystem such as bat ery

bat eries such as lithium-ion bat eries. Although

thermal management.

lithium-ion bat eries are widely used for electric

This paper describes an approach to

vehicles, there is no testing standard for those

determine the bat ery load profile comprising

bat eries [10]. The bat ery test profiles presently

complex charge-discharge wave from real-world

base on constant current or step response

technique which does not represent the real-

world condition. They may be used to investigate

The Second TSME International Conference on Mechanical Engineering

19-21 October, 2011, Krabi

2. Vehicle Dynamics Modeling

speed, x is the vehicle speed, and Jred is the

The vehicle dynamic model can be

reduced mass moment of inertia at wheel.

derived from Newton's second law considering

The vehicle considered in this work is

all the forces applied upon the vehicle. It should

the two year used HONDA Jazz that will be

be noted that only the longitudinal dynamic is

converted to a pure electric vehicle. The existing

sufficient to investigate the bat ery load profile.

engine will be replaced with a 40kW new

With this the complex and uncertain parameters

developing motor. The vehicle uses a 100 cell

as well as the simulation time can be reduced.

lithium-ion bat ery (type: LiFeYPO4) as power

The total resistance forces acting on the

source. The total capacity is 60Ah. The vehicle

vehicle are rolling resistance, aerodynamic

uses the original transmission modified to use

resistance, and grade resistance force, as

the 3rd gear ratio. The vehicle specification is

demonstrated in Fig. 1.

shown in Table 1. Table. 1 Vehicle specification

Value/Description

2 Weight distribution 62/38 (%)

4 Drag coef icient

Fig. 1 Resistance force acting on the

Hence, the vehicle dynamic equation

can be obtained as

3.461, 1.869, 1.303

F F

F F F Eq. (1)

8 Final drive ratio

F mg( f f x)sgn(x) mgsin

A (x x )2 sgn(x) (m

continuous power

roll is rolling resistance, Fad is the

aerodynamic resistance, F

resistance, m is the vehicle mass, g is the

12 Battery Capacity 60 (Ah)

natural acceleration, is the angle of grade, f

13 Number of cells

14 Battery weight

1 are the rolling coef icients, is the air

density, Cd is the aerodynamic drag coef icient,

Af is the vehicle frontal area, x is the wind

simulations there are various types of

mathematical models available. In this work the

The Second TSME International Conference on Mechanical Engineering

19-21 October, 2011, Krabi

vehicle model was created by using a transient effort-flow refer to [1]. Ef ort-flow in the model refers to the combinations of torque/angular speed, force/velocity and voltage/current.

The basic configuration of the electric

vehicle used for simulation is illustrated in Fig. 2. Overall system is modeled in a MATLAB/ Simulink environment.

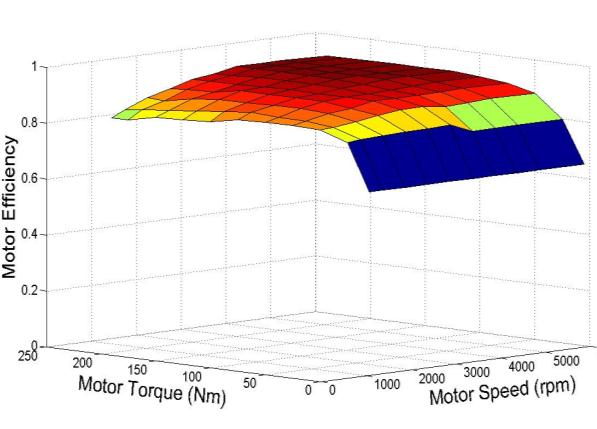

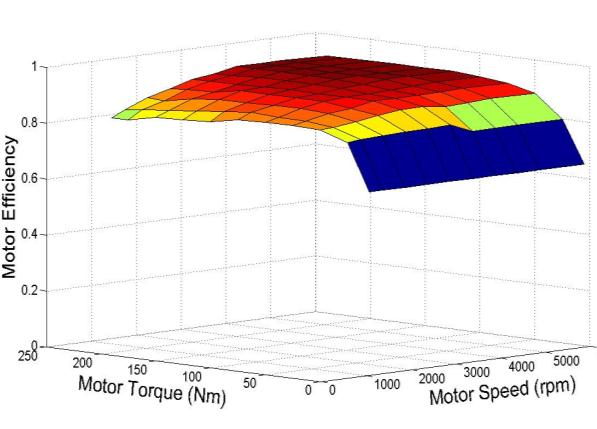

Fig. 3 Efficiency map of the electric motor

3. Battery Modeling

3.1. Battery Model

A bat ery model calculates the bat ery

variables like current, voltage, and the battery

temperature. The bat ery is modeled as an equivalent circuit with a bat ery internal

resistance, as shown in Fig. 4. The model uses

Fig. 2 Electric vehicle configuration

data from experiment described in the next

Vehicle system models typically contain

a mix of empirical data, engineering assumptions, and physical based parameter and

algorithms. Driven by the need for fast

simulation times, complex components such as motor are typically simulated using empirical data in form of lookup maps. For example, the

electric motor is modeled using an efficiency

map handled as a 2-D lookup table indexed by

Fig. 4 Bat ery Model

rotor speed and torque. This map is generally

The model consists of voltage source

obtained via experiments. In our case the

generating an open-circuit voltage (OCV) and a

efficiency map of electric motor is unknown

resistor representing the internal resistance (R).

because the motor is presently constructing.

Both parameters can be described as a function

Therefore the scaling of torque to provide the

of state of charge (SOC) and temperature. The

required maximum power has been done. This

internal resistance is considered separately

type of scaling is valid only for the same motor

between charge and discharge process.

type and in the neighborhood near the actual

The state of charge was estimated by

parameter. The efficiency map of the electric

coulomb counting (current based SOC

motor is shown in Fig. 3.

estimation). The SOC is obtained by measuring

the current flowing into and out of a battery and

The Second TSME International Conference on Mechanical Engineering

19-21 October, 2011, Krabi

integrating this current over time and then

The system consists mainly of power

subtracting it from the charge in a fully charged

supply and electronic load which connected to

bat ery [4]. The other methods of SOC

PC via GPIB. The output voltage range and the

determination can be found in [5].

maximum current rating of those machines are

The temperature is obtained by using

0-60Vdc and 120A respectively. Labview was

bat ery thermal model which describes the heat

used to define the test procedure and log data.

transfer process. The heat is generated from

The tested specimen is a 5 cell series

bat ery due to electrochemical reactions and

connected LiFeYPO4 with a capacity of 60 Ah.

resistive heating which causes increased bat ery

The bat ery core is covered by poly-propylene

temperature [6]. In practice the heat dissipation

case which has low thermal conductivity. During

is best estimated from values of the current and

the test the bat ery was placed in a temperature-

voltage [7], according to

control cabinet. The test cycles is shown in Fig.

where V is the instantaneous cell potential, Voc is

the open-circuit voltage.

The heat dissipation is conducted from

the internal bat ery to the bat ery case and then

convected from the case's surface to the air.

3.2. Experiment Setup

To characterize battery parameters for

its model, the step response technique [8] was

employed. The tests were carried out on the

Deep of Discharge, DoD (%)

testing system as shown in Fig. 5.

Fig. 6 Bat ery test cycle as function of DoD

Fig. 7 Bat ery test cycle as function of time

The test started with the discharge

Fig. 5 Testing system configuration

process. For each test cycle the constant current

of 0.5C (30A) is applied and was paused for one

The Second TSME International Conference on Mechanical Engineering

19-21 October, 2011, Krabi

minute at every 10% change in state of charge.

4. Simulation

Measurements were taken every 200ms. The

4.1 Driving Cycle and Battery Load Cycle

test was performed at temperature of 5°C, 25°C

Through the battery load profile of real-

and 40°C. Some initial cycles were applied to

world driving cycles is the aim of this work, the

ensure that the bat ery reaches stable behavior.

standard driving cycles with transient

The voltage response during the pause

characteristic was used to test our model. The

period is used in order to determine the battery

transient cycles give more dynamic changing in

internal resistance. An example of the voltage

load and are based upon real-world data. UDDS,

response during pause period is shown in Fig. 8.

NYCC and CSC cycles are three examples of

transient driving cycle used to define the bat ery

load profile. They were chosen because they are

based upon real-world driving and content a high

portion of with non-aggressive urban and

suburban routes that are suitable for electric

vehicles. UDDS cycle describes an urban route

with cold start and transient phase, NYCC cycle

represents an urban route through New York

Fig. 8 Example of the voltage response

and CSC cycle describes a city suburban route

with lower average speed than UDDS cycle. Fig.

1, V2, and V3 in Fig. 8 are easily measured.

Both the resistance and the open-circuit voltage

10 shows UDDS cycle as an example.

(OCV) are assumed to be constant over the

pulse period. Voltage dif erent at the beginning

of the pulse is also assumed at the end of the

pulse. The internal resistance after analysis the

test data is shown in Fig. 9. For other methods

for resistance estimation can be found in [11].

Fig. 10 An example UDDS cycle

A bat ery load profile used by the

vehicle can be determined by using one of these

driving cycles as an input to the simulation. The

load profile results are shown in Fig. 11-13. The

simulation was set up with a full battery and a

temperature of 25°C.

Deep of Discharge, DoD (%)

Fig. 9 Internal resistance in case of discharge

The Second TSME International Conference on Mechanical Engineering

19-21 October, 2011, Krabi

the vehicle dynamic simulation must be filtered

while still maintaining the typical load

characteristic. The filter model with filter and

stair-step function was developed for this

purpose. It performs an online analysis to meet

the requirement of hardware in the loop

simulation in the future. Fig. 14 shows a close

up view of a portion of the filtered and unfiltered

Fig. 11 Battery load profile, UDDS

load profile for UDDS cycle.

Fig. 14 Unfiltered and filtered battery load profile

Fig. 12 Bat ery load profile, NYCC

The peak current of unfiltered and

filtered profile are 95.06 A and 96 A, while the

average current are 18.85 A and 18.64 A

respectively. This guarantees correctness and

stability of the filter model.

Fig. 15-17 shows the distribution of the

filtered bat ery load profile for all three driving

Fig. 13 Bat ery load profile, CSC

4.2 Cycle Filtration

In the practice the high dynamic load

cannot use directly due to the limited capability

of bat ery testing machines. To enable the use

of widely available battery testing machines the

minimum sampling period of load profile for input

to the testing machine should be 2 seconds and

the profile should be rectangular wave. To meet

Filtered battery current (A)

these requirements the battery load profile from

Fig. 15 Load distribution of UDDS cycle

The Second TSME International Conference on Mechanical Engineering

19-21 October, 2011, Krabi

been done to provide input parameters for the

The vehicle dynamic model and the

bat ery model are a core of this vehicle system

simulation. In the vehicle dynamic model only

the longitudinal dynamic is sufficient to

investigate the battery load profile, while an equivalent circuit with an internal resistance is

considered in the bat ery model.

Filtered battery current (A)

The experiment has been conducted to

Fig. 16 Load distribution of NYCC cycle

get the bat ery properties. The test methodology

relies on the current pulse relaxation technique

to determine the battery characteristics.

Accordingly, using this methodology, the

bat ery load profile correspond to actual driving

condition or any driving cycle can be predicted

and can be used for bat ery testing. This creates

a new aspect to evaluate advanced batteries for

power train application.

6. References

Filtered battery current (A)

Fig. 17 Load distribution of CSC cycle

[1] Gao, D.W., Mi, C. and Emadi, A. (2007).

All three driving cycles have the most

Modeling and Simulation of Electric and Hybrid

common current value with in the same range.

Vehicles, Proceedings of the IEEE, vol.95(4),

For UDDS cycle the bat ery current varies widely

April 2007, pp. 729 – 745.

between -15 and 96 A, whereas the most

[2] Johnson, V.H., Pesaran, A.A. (2000).

common value lies between 2 to 6 A. NYCC and

Temperature-Dependent Battery Models for

CSC cycles show narrower current distribution

High-Power Lithium-Ion Batteries, paper

than the UDDS cycle. The vehicle takes current

presented in the 17thElectric Vehicle Symposium,

from the bat ery at 2 to 6 A through about half of

Montreal, Canada.

[3] Johnson, V.H. (2002). Battery performance

5. Conclusion

models in ADVISOR, Journal of Power Sources,

The present paper examined the bat ery

vol.110, pp. 321 – 329.

load profile of a vehicle driving in the real world.

[4] Bergveld, H.J., Kruijt, W.S., Notten, P.H.L.

To predict the bat ery load a vehicle system

(2002). Battery Management Systems: Design by

simulation was developed while many tests have

Modelling, Philips Research Book Series Volume 1, ISBN: 1402008325, Springer

The Second TSME International Conference on Mechanical Engineering

19-21 October, 2011, Krabi

[5] Pop, V., Bergveld, H.J., Danilov, D., Regtien,

[9] Duvall, M.S. (2005). Battery Evaluation for

P.P.L., Notten, P.H.L. (2008). Battery

Plug-In Hybrid Electric Vehicles, Vehicle Power

Management Systems: Accurate State-of-Charge

and Propulsion, IEEE Conference, pp. 338 –

Indication for Battery-Powered Applications,

Philips Research Book Series Volume 9, ISBN:

[10] Morita, K., Akai, M., Hirose, H. (2009).

1402069448, Springer

Development of Cycle Life Test Profiles of

[6] Pesaran, A.A. (2002). Battery thermal models

Lithium-ion Batteries for Plug-in Hybrid Electric

for hybrid vehicle simulations, Journal of Power

Vehicles, EVS24 International Battery, Hybrid

Sources, vol.110, pp. 377 – 382.

and Fuel Cell Electric Vehicle Symposium

[7] PCM Thermal Control of Nickel-Hydrogen

[11] Schweiger, H.G., Obeidi, O., Komesker, O.,

Batteries, Division of Technical Services and

Raschke, A., Schiemann, M., Zehner, C.,

Planning, PL-TR-93-1075, Energy Science

Gehnen, M., Keller, M., Birke, P. (2010),

Laboratories Inc., Final Report 1993

Comparison of Several Methods for Determining

[8] Doerffel, D. (2007). Testing and

the Internal Resistance of Lithium Ion Cells,

Characterisation of Large High-Energy Lithium-

Sensors 2010, 10, ISSN 1424-8220, pp. 5604 –

Ion Batteries for Electric and Hybrid Electric

Vehicles, PhD Thesis, University of Southampton

Source: http://rcme.engr.tu.ac.th/TSME-ICoME%20Web/full_paper_file/ETM/ETM18%20920-1611-1-RV.pdf

Vol. 7 No. 1 is new AHMOPI President By : Camille "Camry" T. Silos IntelliCare Chairman level-playing field for all and President, Mario M. Silos, companies who are a part ofis the newly-elected president of AHMOPI to compete with eachthe Association of Health other without undue advantageMaintenance Organizations of or disadvantages, as well asthe Philippines, Inc. (AHMOPI). providing a venue where theIt is a non-stock and non-profit members can give advice toumbrella organization composed other members in the associationof all the major HMOs and other and discuss various relevantsimilarly-engaged pre-paid topics with each other. Lastly,healthcare companies in the AHMOPI is a vehicle by whichcountry.

RASHMI DESHMUKH, MD KATHLEEN FRANCO, MD* Department of Psychiatry and Psychology, Head, Section of Consultation-Liaison The Cleveland Clinic Psychiatry, Department of Psychiatry andPsychology, The Cleveland Clinic Managing weight gain as a sideeffect of antidepressant therapy ■ A B S T R AC T EIGHT GAIN IS A SERIOUS concern for