Encyfelobalt mykloprefiks i pregutturale mememerelasjoner

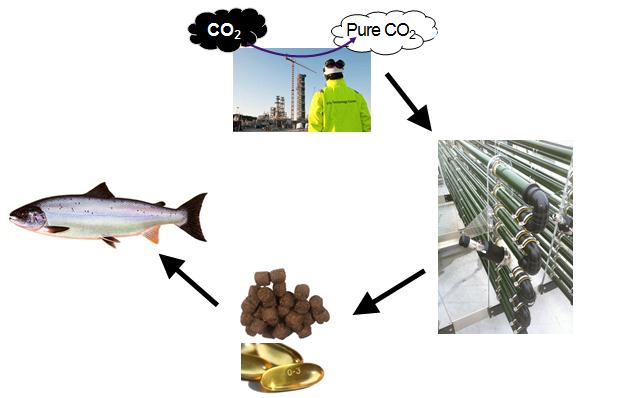

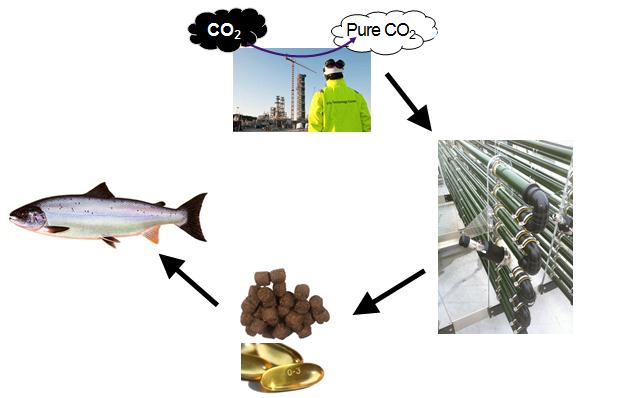

CO2 to Bio

Microalgae as an omega-3 rich feedstock -

integrating CO2 sequestration and aquafeed production

Project final report

January 2012

Prepared by Hans Kleivdal, Uni Miljø Svein M. Nordvik, Nordhordland Handverk- og Industrilag Trond Mork-Pedersen, Nofima Anders Haugland, BTO

CO2 to Bio

In 2010 the new gas-fired power plant at Mongstad (EVM) started the production of power and steam. In this respect, the Norwegian Government also decided to establish a Technology Center

for carbon capture at Mongstad (TCM) in order to test and improve CO2 capture technologies. TCM will open in May 2012, and is designed for the capturing of up to 100.000 tons of CO2. Fur-

thermore, the planning of a full-scale CO2 capture facility at Mongstad scaled to capture one

million tons of CO2 is ongoing, and involves transport and subsurface storage in geological for-

mations in the North Sea. Until further – the captured CO2 from TCM will be released into the

air during the test period.

The unique access to large amounts of pure CO2 can put Mongstad in a valuable position,

as CO2 can be used as a raw material for several applications. The industry consortium "Nord-

hordland Handverk- og Industrilag" (NHIL ) has suggested that using CO2 as a resource is a

more sustainable and economically viable alternative to subsurface storage, and have evaluated

several alternatives for the use of captured CO2 together with research institutions. For this purpose,

NHIL and TCM signed a preliminary agreement for use of up to 30.000 tons of captured CO2.

The global demand for food is increasing together with the world population. Norway is a

valuable contributor of farmed seafood to the global market, and the aquaculture industry expe-

rience an increasing demand. However, while the market demand of omega-3 fatty acids is in-

creasing rapidly, the global resources of fish oil and omega-3 used as aquafeed ingredients are

limited. Therefore, one of the largest challenges for the salmon industry is to develop new and

reliable sources of omega-3 for continued aquafeed production. Our focus has been on microal-

gae as they are the primary producers and main source of omega-3 in the ocean.

The purpose of this preliminary project "CO2 to Bio" has been to provide an as-

sessment of an industrial scale production of omega-3 rich biomass from microal-

gae, based on captured CO2 and available resources at Mongstad, for the production of omega-

3 supplements in aquafeed. The study has been divided in seven work package reports, where

the findings and conclusion is given in the Executive Summary. The pilot project "CO2 to Bio" started in June 2011 in collaboration between NHIL, Uni Research, Nofima and Bergen

Teknologioverføring, and was financed by the above organizations and Sparebanken Vest.

The overall report concludes that the industrial production of microalgae at

Mongstad can be a valuable contribution to the aquaculture industry. CO2 is vital

input for photosynthetic algae production, and will also result in a positive climate effect. By

integrating CO2 sequestration and production of omega-3 rich algae biomass for aquafeed, this

project initiative can make it possible for the Norwegian aquaculture industry to market the salmon as a good health food product also in the future. However, this will require research efforts

to develop biological assets as well as the current production and processing technology. Several

research institutions and industrial companies in Bergen have a well-established competence

within this field and can, through national and international collaborations, provide the re-

search and development required to fulfill this project. The company "CO2Bio AS" is now established as a result of this pilot project with industrial par-ticipation including Ewos AS, Grieg Seafood ASA and Salmon Group AS. The first step will be to

establish a pilot plant and a research group for the production of algae, biomass and processing

before the main target; production of omega-3 fatty acid in large scale at Mongstad.

We wish to thank CO2 Technology Centre Mongstad (TCM) for their valuable cooperation, and

the engineering consultants at Akvator AS for their contribution.

Nordhordland Handverk- og Industrilag (NHIL)

The following have contributed to the preparation of this report "CO2 to Bio":

Steering Committee:

Hans Kleivdal Uni Research/Uni Miljø

Trond Mork-Pedersen Nofima Anders Haugland BTO

Svein M Nordvik NHIL

Other contributors:

Caspar Lund

Marie- Lise Schläppy

Uni Research/Uni Miljø

Friederike Hoffmann

Uni Research/Uni Miljø

UiB, Institutt for Biologi

Svein Rune Erga

UiB, Institutt for Biologi

Katerina Kousoulaki

Øystein Høstmark Nofima

Henning Egede-Nilsen

Eyolf Langmyhr Nofima

Tor Andreas Samuelsen

Einar Wathne Ewos Group

University of Wageningen

We also wish to thank the Board and the Energy and Environment committee in Nordhordland

Handverk- og Industrilag for the valuable contribution to facilitate this report.

CO2 to Bio

Contents

Executive summary 2 pages

Work package 1 - Location 16 pages

Work package 2 – Production methods 23 pages

Work package 3 – Algae 27 pages

Work package 4 – Biomass aspects 32 pages

Work package 5 – Costs and markets 14 pages

Work package 6 – Environmental aspects 9 pages

Work package 7 – Conclusions 5 pages

Executive summary

The purpose of the pre-project "CO2 to Bio" is to provide an assessment of the proposed industrial

production of algal biomass at Mongstad based on captured CO2 and residual heat. These unex-ploited resources are considered as waste, but can be valuable inputs in up-scaled algal production.

The algal biomass is rich in omega-3 and can be a valuable ingredient for the aquafeed market – a

sizeable market where the demand for omega-3 is expected to rise significantly. Our aim was to assess the industrial production of omega-3 fatty acids and other high-value prod-ucts from microalgae, and the work was divided in 7 work packages – including this summary.

WP1 - Location

Mongstad is a suitable location for industrial microalgae production, and will benefit from the ex-

isting industrial infrastructure. A future microalgae production facility will have to be connected to

the current TCM pilot facility and future large scale facilities for the supply of captured CO2. In ad-dition, microalgae facility will need a steady supply of residual heat, cold seawater and freshwater,

and the ability to handle large volumes of waste water at suitable treatment. The weather condi-

tions are challenging with low temperatures and limited solar irradiation. However, the algal pro-

duction will benefit from long daylight hours during the summer period. Recommendations:

The planning of production facilities must be conducted in dialogue with industrial initiatives

at Mongstad, as well as the municipalities and land owners (Statoil).

Production facilities should be inside a greenhouse to protect PBRs and control the temperature.

WP2 – Production methods

The most promising production systems are closed photobioreactors (PBR) that are highly con-

trolled systems made of transparent tubes were the algae is exposed to natural or artificial light. The main challenge is to reduce production costs by lowering the energy demanding steps and in-

crease the photosynthetic efficiency and biomass yield. The existing PBR systems must be im-

proved before they are suitable for large scale production of microalgae for the bulk market. The

current production cost estimate is 4.15 €/kg dry weight biomass, but technologists aim to reduce

cost down towards 1.0 €/kg. The AlgaePARC (NL) focus on cost-efficient production systems suit-

able for industrial purpose, and have a strong international position and scientific competence within this field. We propose to establish a pilot production facility to develop and compare prom-

ising PBR designs, aiming at a cost-effective production system suitable for up-scaled production at

Mongstad. A collaboration with AlgaePARC will therefore be beneficial - both for establishing the

Mongstad pilot production facility and for the following research activity. Recommendations:

Establish a pilot production facility for the development and comparison of industrial microal-

gae production systems at Mongstad.

Enter collaboration with AlgaePARC in the development of the Mongstad pilot facility. Seek national collaborators in the establishment of a national forum for microalgae. Develop an R&D strategy and detailed plan to maximize the efficiency of the future research

efforts and reduce the risks at an early stage.

WP3 – Algae

A comprehensive overview of algae growth requirements and nutritional qualities related to aquafeed

has been given by algal experts at the University of Bergen. The optimization potential of the produc-tion efficiency lies not only on the production systems, but through screening and selection of the

most production-efficient algal strain in collaboration with Bergen Marine Biobank. Furthermore,

the algae can be stressed to produce more omega-3 through just before harvest. Recommendations:

CO2 to Bio

Several algae with high omega-3 levels are suitable as aquafeed ingredients, of which four local

algae are recommended; P. lutheri, P. tricornumtum, I. galbana and Nannochloropsis spp.

Develop industrial scale procedures to induce high omega-3 levels by metabolic stress.

WP4 – Biomass

All aspects of the handling and processing of the algae biomass from harvesting, dewatering, dry-

ing, optimization of nutrients and digestibility, oil extraction procedures up to the stage of incorpo-

ration into the aquafeed has been elaborated in a comprehensive WP-report.

The water content in the algal biomass is very high, and harvesting by centrifugation is a highly

energy demanding step that drives the overall cost picture. A main challenge is therefore to signifi-

cantly reduce the costs associated with water removal. Another challenge is to break open the tough

cell wall of the algal cells during processing, in order to release valuable nutrients and make these available for digestion or further processing. Nofima are highly experienced in marine biomass

processing, and will work to convert their competence towards algal biomass. Once the various

product alternatives are developed, the characteristics during the pellet extrusion will need to be

investigated. Furthermore, the product's nutritional value as an input in fish feed must be fully

documented in feeding experiments with salmon. Based on their nutritional quality, four algae

were recommended and were the same algae that were recommended under WP3.

WP5 – Costs and markets

The price of fish oil is expected to increase significantly in the next coming years due to an upcoming

shortage of fish oils. This is because the production of fish oil, which comes from wild caught fish such

as anchovies, is already at or close to maximum levels. At the same time the demand for omega-3 con-

tinues to rise, much driven by an increasing demand from pharmaceutical industry and the health food sector which uses it as in nutritional supplements. The world market for farmed salmon is also growing (annually about 6%), and the salmon industry has

a large export share (> 95%). The growing salmon market will directly affect the aquafeed industry,

which will challenged by having to increase production and face the expected shortage of fish oil at the

same time. For the long run, new and sustainable omega-3 sources must be developed if the Norwegian salmon industry still wants to market farmed salmon as a good health food product in the future. Omega-3 production based on algal biomass is innovative, sustainable, has a good environmental

profile and will be free of contaminants often associated with fish oil. Our competitive advantage is a

significant and steady supply of CO2, residual heat at Mongstad. Furthermore, we have an ongoing dialogue with the affected aquaculture-industries to ensure that the products are customized to meet

their needs and requirements. Establishing a pilot plant where technology can be tested, develop

optimized algae cultures and production processes for full-scale production, will require an in-

vestment of 11 MNOK. The pilot plant will be ready at the end of 2012 and will be operating for 3

years. Operation of the pilot plant will cost approximate 8 MNOK. The technology development

of cost-effective microalgae production systems at the pilot facility, supported by waste resources, is expected to lower costs and increase productivity to make the algal biomass competitive on world

WP6 – Environmental aspects

The industrial production of microalgae use captured CO2 and reduces waste greenhouse gas emis-

sions. The microalgae omega-3 is therefore a sustainable ingredient in aquafeed, and will be an

ecofriendly alternative to replace currently imported fish oil recovered from wild caught fish. It is recommended to conduct a full scale LCA to document the proposed environmental benefits

WP7 – Conclusion

Based on the "CO2 to Bio" findings and assessments, we recommend establishing of a pilot facility

for industrial production of microalgae at Mongstad, which will provide a basis for competitive

production of omega-3 for use in aquafeed. This should be done in close cooperation between re-

search institutions and the aquaculture industry. It is recommended that further work is being managed by the newly founded company, CO2Bio AS,

where the central industrial stakeholders are shareholders.

CO2 to Bio

Work Package 1 - Location

Ver. HK 280911

Prepared by Hans Kleivdal, Marie-Lise Schläppy, Friederike Hoffmann, Uni Miljø Svein M. Nordvik, Nordhordland Handverk- og Industrilag

Contents

1.1 Mongstad Industrial area _ 5

1.1.1 Mongstad _ 5

1.1.2 Mongstad oil refinery 5

1.1.3 CO2 Technology Centre Mongstad (TCM) 5

1.2 Available resources for exploitation in microalgae cultivation _ 7

1.2.2 Heat/steam 7

1.2.3 Cold seawater intake 7

1.2.4 Water discharge 7

1.2.5 Electricity _ 7

1.2.6 Sun light 7

1.3 Available area and infrastructure facilities 7

1.3.1 Infrastructure assets at Mongstad 7

1.3.2 Area available for pilot algae test facility _ 8

1.3.3 Area available for large-scale algae production facility 8

1.4 Climate data _ 9

1.4.1 General _ 9

1.4.2 Solar irradiation _ 9

1.4.3 Photosynthetical y active radiation (PAR) at Mongstad 9

1.4.4 Hours of daylight _ 11

1.4.5 Cloud cover and precipitation _ 11

1.4.6 Temperature 12

1.4.7 Conclusion on climate data 12

1.5 A biotechnological "moonlanding" at Mongstad _ 13 1.6 Challenges and recommendations _ 13

1.6.1 Integrating microalgae production with existing industrial activity _ 13

1.6.2 Area for microalgae production _ 14

1.6.3 Weather conditions _ 14

1.6.4 Low temperatures 14

1.6.5 Low solar irradiation values 14

CO2 to Bio/WP1 - Location

1.1 Mongstad Industrial area

1.1.1 Mongstad

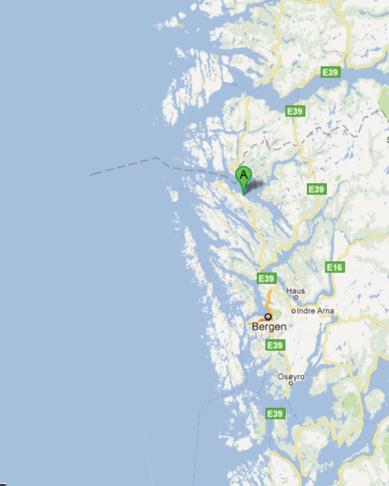

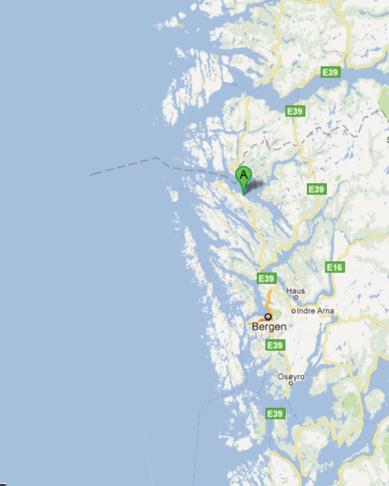

Mongstad (60°48'47" North, 5°1'14" East) is located on the south-west coast of Norway, about

65 km North of Bergen which is the second largest city in Norway (figure 1). Bergen is the ad-

ministrative centre of Hordaland County, recognized as the unofficial capital of Western Nor-

way. At Mongstad, the industrial site is located in the municipalities of Lindås and Austrheim.

The industrial site features an oil refinery for Statoil with port facilities1, with an unexploited

area in the South that is relatively flat and marshy, partly covered with heather and conifers.

1.1.2 Mongstad oil refinery

At Mongstad, Statoil has a crude oil terminal with a capacity of 10 million barrels/year2. The

port at the support facility Mongstad is the largest in Norway, measured in tonnage. The refin-

ery at Mongstad is modern, and has been extensively upgraded, with a capacity of 10 million

tonnes crude oil per year. The refinery is the largest in Norway, though medium sized by Euro-

pean standards. It is owned by Mongstad Refining, in which Statoil has a 79% ownership share

and Shell 21%. All the crude oil refined at Mongstad comes from the North Sea. The largest pro-

duction is petrol, diesel, jet fuel and light petroleum products. The heaviest components are

used to make petrol coke, an important ingredient in anodes for aluminum production. In 2010, Statoil and DONG Energy opened Mongstad power station, a natural gas-fired thermal

power plant, to provide the site with heat energy and electricity, as well as to the Troll gas field.

The station is owned and operated by DONG Energy, and will be integrated in the Statoil refin-

ery. The power station will have an installed effect of 280 MW in electricity production and 350

MW in heat. The energy will be used to operate the Mongstad Refinery as well to supply the

Troll Gas Field with power. The plant will use 0.7 normal cubic meter (BCM) gas per year. Emis-sions of CO2 will be up to 1.2 million tons.

1.1.3 CO2 Technology Centre Mongstad (TCM)

The CO2 capture at Mongstad is central to the Norwegian government's efforts to obtain tech-

nologies that can reduce emissions of CO 3

2 , in line with Norway's commitment to the Kyoto Pro-

tocol4. Development of technologies for CO2 capture is difficult and there will always be uncer-

tainty involved in the development of technologies from the research stage to industrial scale.

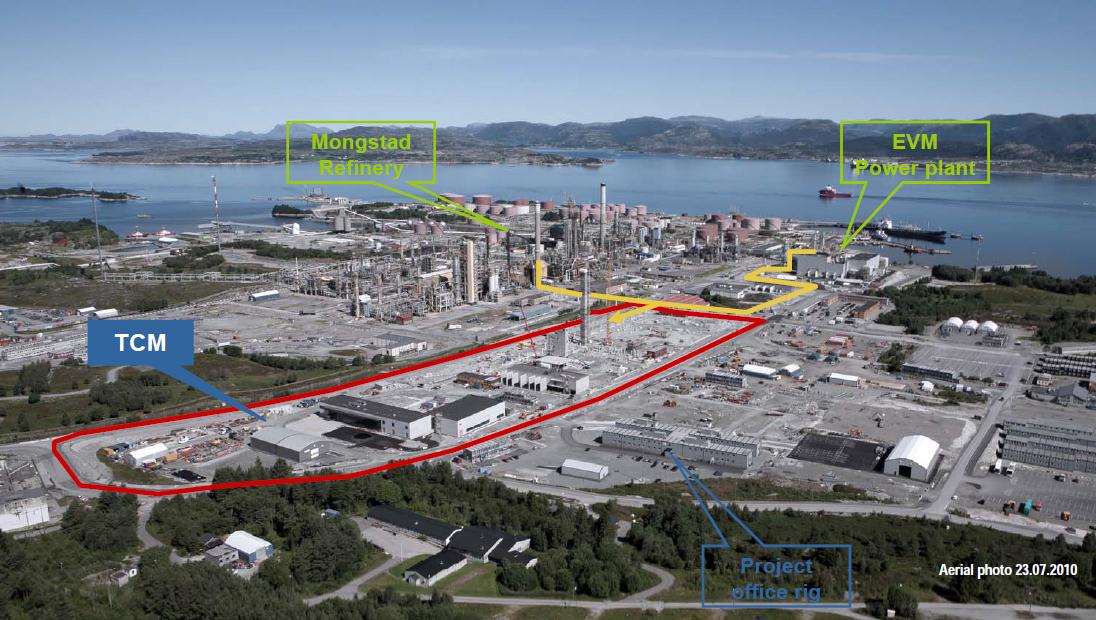

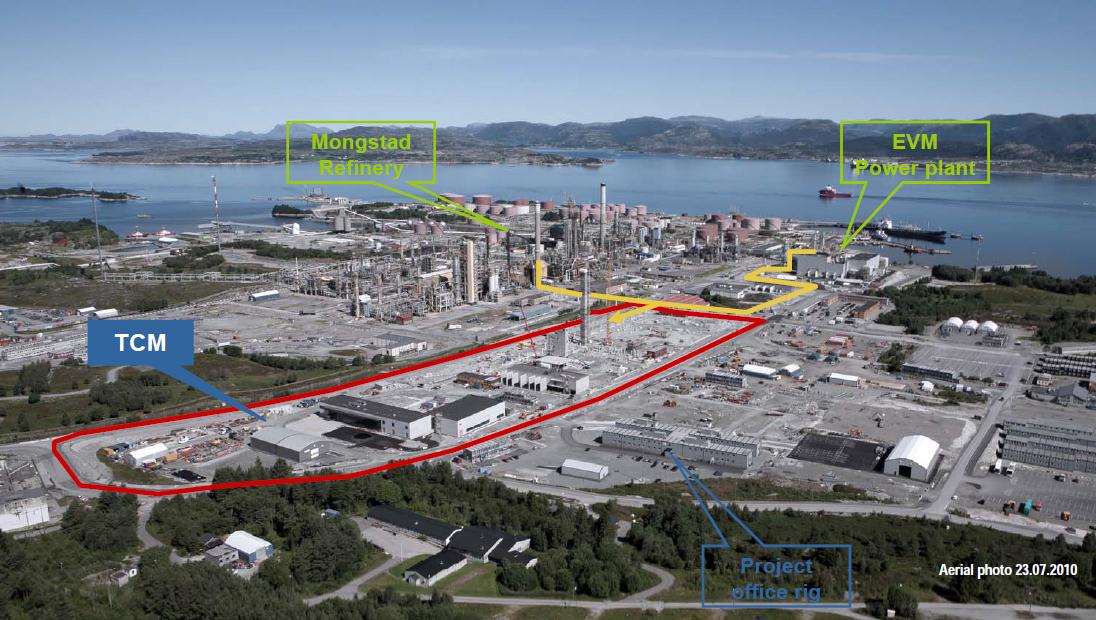

Fig 1: Mongstad Industrial site. A) Location of Mongstad, 65 km North of Bergen, on the south-west coast of Norway; 60°48'47"

North, 5°1'14" East, at 10 meters above sea level. B) Aerial photo taken showing Mongstad industrial site from South-East. The

Statoil oil refinery shown in the North (top) and the Mongstad support base in the South, surrounded by undeveloped industrial land.

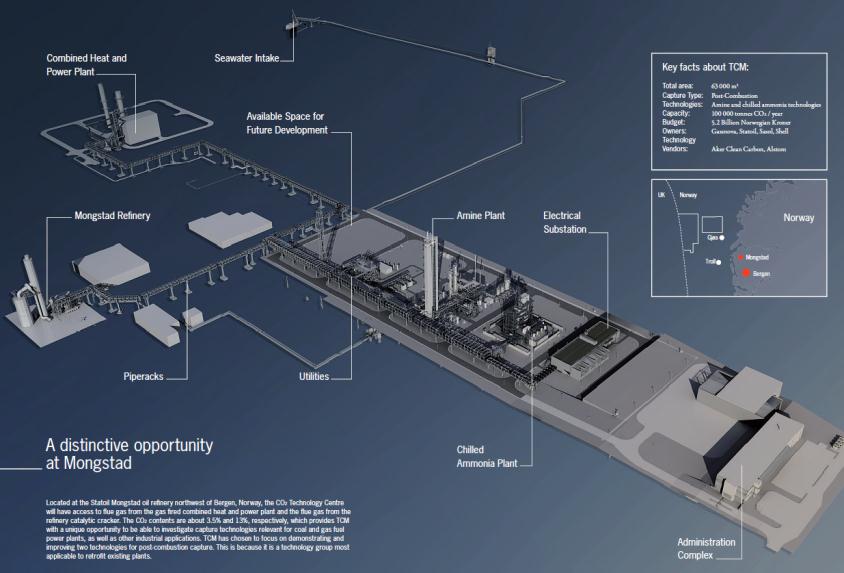

Fig 2: CO2 Technology Center Mongstad seen from the South. Location of the TCM facility receiving flue gas from both the

Mongstad oil refinery and the EVM combined heat and power station. Source

The aim of the Norwegian government with the technology center is to create a venue for target-

ed development, testing and qualification of the technology for CO2 capture. It also aims to con-

tribute to the international dissemination of these experiences so that the cost and risk of full-

scale CO2 capture can be reduced. In 2007 Statoil entered into an implementation agreement in cooperation with the Norwegian

State, to develop a test centre at Mongstad for test of carbon dioxide capture technologies. The

CO2 Technology Centre Mongstad DA (TCM DA) was established in 2009 with the main ambi-

tions being to test, verify and demonstrate CO2 capture technology owned and marketed by ven-

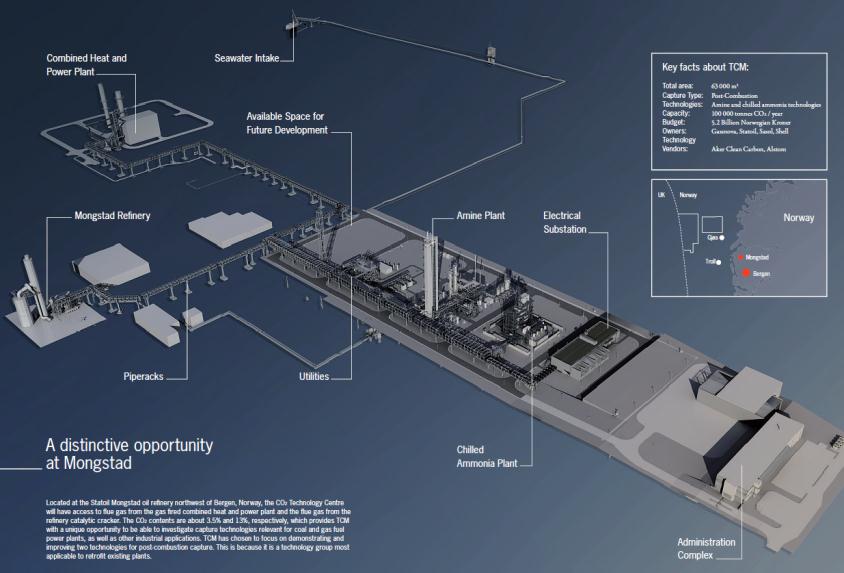

dors, and encourage the development of the market for carbon capture technology5. The CO2 Technology Centre Mongstad will be operational from 2012, and will have access to flue gas from the gas fired combined heat and power plant and the flue gas from the refinery catalyt-

ic cracker (figure 2). The CO2 contents are about 3.5% and 13%, respectively, which provides

Fig 3: Schematic view of CO2 Technology Centre Mongsta The construction of the two capture-technology facilities is close to

being finalized. The available space for future developments is indicated in the centre.

CO2 to Bio/WP1 - Location

TCM with a unique opportunity to be able to investigate capture technologies relevant for coal

and gas fuel power plants, as well as other industrial applications. TCM has chosen to focus on

demonstrating and improving two technologies for post-combustion capture. This is because it

is a technology group most applicable to retrofit existing plants.

The construction work is still ongoing, and recently (June 2011) the construction of the first CO2 capture facility was finalized (figure 3). This is the post-combustion capture technique using

amines, where Aker Clean Carbon is the provider of the amine unit. The second technology that

will be tested is based on separating CO2 from the exhaust gases using chilled ammonia as the

solvent to absorb the CO2. The Chilled Ammonia post-combustion technology is provided and

operated by Alstom.

1.2 Available resources for exploitation in microalgae cultivation

1.2.1 CO2

The TCM will test two different CO2 capture technologies with the deigned capacity to capture

approx 100 000 tons per year, where there is an agreement between NHIL and TCM to deliver up to 30 000 tons capture CO2 for development of CO2 utilizing technologies. The CO2 is esti-

mated to about 99,7% purity with differences in trace elements pending on the capture technol-

ogy used. TCM has applied for a permit to release captured CO2 in to the air until storage solu-

tions is in place.

1.2.2 Heat/steam

The TCM have access to steam from the oil refinery. The steam is delivered to the TCM facility in

pipes (figure 3),.

1.2.3 Cold seawater intake

The TCM have access to seawater from an intake at 40 meter below sea level (4-8°C) that will be

used as cooling water for TCM.

1.2.4 Water discharge

The seawater intake system also has the capacity to return seawater at 30 meter below sea level.

An important issue that requires consideration if pre-treatment is required before used sea wa-

ter drained from algal cultivation reactors can be emitted into the sea.

1.2.5 Electricity

The TCM have an own electrical substation delivering 10 MW to the test technologies, .

1.2.6 Sun light

The solar irradiation factor is dealt with in more detail in section 1.4 Climate conditions.

1.3 Available area and infrastructure facilities

1.3.1 Infrastructure assets at Mongstad

Infrastructure and location makes the Mongstad site particularly suitable for algal production

with supply of large quantities of pure CO2, steam and cooling water. Mongstad can be reached

by car in about 50 minutes from Bergen city. There are also good port facilities for transport of

biomass or algae based products to customers in Norway and abroad at the Mongstad base.

1.3.2 Area available for pilot algae test facility

The TCM facility has available space for future developments, and has set apart space for a pos-

sible third technology, or several smaller test facilities. Part of this area may be made available for a pilot algae test, with a possible direct access point to CO2.

1.3.3 Area available for large-scale algae production facility

There are large open areas of land around the refinery, which is suitable for algae production.

Lindås and Austrheim their new land-use plans for the Mongstad in 2010 arranged for nearly

3,000 acres of new commercial space. In addition, several hundred acres of undeveloped indus-

trial land is available between the oil refinery and the Mongstad base from the previous regula-

tions (figure 4).

Fig 4: Mongstad Industrial site – aerial photo from E. The Statoil Mongstad Oil Refinery is seen in N-W (top rigth), while the

Mongstad Base is seen from the S (bottom left). The surrounding area is largely exploitable for further industrial use.

CO2 to Bio/WP1 - Location

1.4 Climate data

1.4.1 General

The climate at Mongstad is coastal with fronts coming in from the North Sea mainly from the

West and North. The national weather stations with long-time registration of climate data clos-

est to Mongstad are the island of Fedje6 (17 km West of Mongstad) and the village Isdalstø (30

km South of Mongstad). Climate data of these permanent weather stations are available from

the Norwegian Meteorological Institute through their web resources. The production of microalgae at Mongstad will be affected by solar irradiation, temperature,

and precipitation.

1.4.2 Solar irradiation

The production of microalgae will be possible to regulate by the supply of nutrients and CO2 in

relation to the need for growth. The limiting factor is thus in practice the supply of light energy

for photosynthetic microalgae, and the growth rates can be directly proportional to the irradia-

tion intensity7. Only the solar radiation in the visible range from 400-700 nm is absorbed by microalgae pigments, and this wavelength range is therefore called the photosynthetically ac-

tive radiation (PAR). In addition, the irradiation angle is an important factor for the actual ir-

radiation intensity.

1.4.3 Photosynthetical y active radiation (PAR) at Mongstad

From the Photovoltaic Geographical Information System under the EU Joint Research Centre8,

the solar irradiation was calculated for Mongstad showing a strong seasonal variation, with the

lowest in December (124 Wh/m2/day on a horizontal plane) and the highest values in June (5150 Wh/m2/day on a horizontal plane). This is comparable to the base case of Norsker et al

(2010) for Eindhoven in the Netherlands.

Fig 5: Average monthly irradiation at Mongstad. Data, given in kWh/m2/day, calculated from the Photovoltaic Geographical

Information System under the EU Joint Research Centr 7 Norsker et al, (2010)

Fig 6: Height of sun at Mongstad through the year. Data calculated from the Photovoltaic Geographical Information System

under the EU Joint Research Centr

Table 1. Complex data set on the irradiation. Data calculated from the Photovoltaic Geographical Information System under

the EU Joint Research Centr

Hh: Irradiation on horizontal plane (Wh/m2/day)

Hopt: Irradiation on optimally inclined plane (Wh/m2/day)

H(90): Irradiation on plane at angle: 90deg. (Wh/m2/day)

Iopt: Optimal inclination (deg.)

D/G: Ratio of diffuse to global irradiation (-)

TD: Average daytime temperature (°C)

T24h: 24 hour average of temperature (°C)

NDD: Number of heating degree-days (-)

CO2 to Bio/WP1 - Location

Fig 7: Hours of daylight through the year. Data collected from the Gaisma websit

1.4.4 Hours of daylight

The times for sunrise, sunset, dusk and dawn for Bergen (80 km South of Mongstad) show that

there is a strong variation in hours of daylight during the year, with only 1 hour of darkness dur-

ing a daily cycle in June, and only about 6 hours of daylight in December9.

1.4.5 Cloud cover and precipitation

There were no data on cloud cover or hours of sunshine for the weather stations closest to

Mongstad. The precipitation data gives an indirect indication on cloud cover (figure 8), where the precipita-

tion is lowest in June (100 mm/month) and highest in September (275 mm/month) and

throughout autumn.

Precipi 100

Fig 8: Average precipitation at FEdje and Isdalstø through the year. The data points are calculated from monthly normal (aver-

ages from 1961-1990) by the Norwegian Met Institut

Fig 9: Average monthly temperature (red line) at Fedje July 2010 to June 2011. The black line indicates the normal temperature

for comparison10.

1.4.6 Temperature

The normal temperature (average of 30 years, 1961-1990) shows seasonal variations in a rather

small range, with lowest temperatures in January-February of 1-2 ºC and highest in July-August

of 13-14 ºC (figure 9). In the last 12 months, the highest temperature was measured in August

(23.5 ºC) and the lowest in December (-6.6 ºC) (figure 10). The annual average temperature is

Fig 10: Normal temperature (monthly temperature averages from 1961-1990) at Fedje and Isdalstø.

1.4.7 Conclusion on climate data

Due to the location high up in the northern hemisphere, irradiation shows a strong seasonal

variation. This is explained by the seasonal variation of sunrise and sunset with only 1 hour of

darkness during one day and night in June, and only 6 hours of daylight during one day and night in December. In addition the lower solar angle will decrease the irradiation intensity per

m2, compared to areas closer to the equator. Algae cultures will benefit from long hours of day-

light and high irradiance during the summer months. The seasonal temperature varies accordingly, but the total range in average temperature during

the year is low, varying between 2-13 ºC; the annual average temperature is about 7 ºC. The cli-

mate is generally mild, without extreme values. This is beneficial for maintaining stable temper-

ature conditions for algae cultures at the open air. Most precipitation comes in the dark autumn and winter period.

CO2 to Bio/WP1 - Location

Fig 11: Pilot versions of closed industrial cultivation systems. Examples of a horizontal photobioreactor (left) and a vertical

photobioreactor (right) where the microalgae are being circulated in the transparent cultivation tubes – with sunlight and CO2 as the

most important growth factors (source: AlgaePARC).

1.5 A biotechnological "moonlanding" at Mongstad

The Mongstad industrial area has unexploited resources that could benefit a new bioindustry

based on production of microalgae. The purity of the captured CO2 will be most beneficial to the cultivation of microalgae as a direct use of exhaust gases from combustion will also contain oth-

er components (NOx, SOx) that may have a negative effect both on growth effects and the final

product. A cost study from the Netherlands showed that CO2 may represent a significant por-

tion of operating costs - by up to 10% depending on the scale and production system (Norsker et

al, 2011)11. The exploitation of residual heat from cooling water can also be exploited to raise temperatures to the optimum growth temperatures around 20°C, and might also be used as an

asset in dewatering/drying procedures. The industrial infrastructure with port facilities on site, supports good transport alternatives. A large scale production at Mongstad will be based on closed cultivation systems (photobioreac-

tors) – with vertical tubular reactors being the most likely choice (figure 11). The establishment

of a pilot production facility would be the important first step towards an industrial scale pro-

duction of microalgal biomass.

1.6 Challenges and recommendations

This study of the Mongstad locality has been conducted to evaluate the feasibility of producing

microalgae in an industrial setting. Some challenges have been identified and recommendations

on how to meet these will be given below.

1.6.1 Integrating microalgae production with existing industrial activity

A large scale microalgae production facility will have to be connected to the current TCM pilot

facility and future large scale facilities for the supply of pure CO2. In addition, microalgae facility

will need a steady supply of heat/steam, cold seawater and freshwater. The handling of large

volumes of waste water will require suitable facilities for treatment and discharge.

Recommendation: The design and planning of a large scale facility must be conducted in tight

dialogue with current and planned industrial activities at Mongstad.

11 Norsker N-H, Barbosa MJ, Vermuë MH, Wijffels RH (2011) Microalgal production — A close look at the economics.

Biotechnology Advances 29:24-27

1.6.2 Area for microalgae production

A large scale microalgae production facility based on photosynthesis will require large land are-

as around Mongstad industrial site. Recommendation: The area required will be determined through the pilot production phase, but

it is recommended to enter a dialogue with the municipalities and land owners (Statoil) at an

1.6.3 Weather conditions

The weather conditions at Mongstad can be harsh and windy, and can be challenging for outside

PBRs. In addition, snowfall and ice can cause damage to outside installations in general.

Recommendation: Production facilities should be inside a greenhouse to protect the PBRs from harsh weather conditions, low temperatures and photoinhibition.

1.6.4 Low temperatures

The average temperature at Mongstad is far below the recommended temperatures for an opti-

mal microalgae production (20-25°C).

Recommendation: The temperature should be kept stable at 20-25°C by keeping the PBRs in-

side a temperature controlled greenhouse, using steam/warm cooling water from the Mongstad

1.6.5 Low solar irradiation values

The photoactive radiation (PAR) values for Mongstad will be clearly the limiting factor, especial-

ly during the winter and autumn period.

Recommendation: The industrial production of microalgae should be conducted with the supply

of an artificial lightsource. The preferred option should be light emitting diodes (LED) to lower

CO2 to Bio

Work Package 2 – Production methods

Ver. 171111

Prepared by Hans Kleivdal and Marie-Lise Schläppy, Uni Miljø

Contents

2.1 Introduction 5 2.2 Open pond phototrophic algae production 6

2.2.1 Open pond advantages 6

2.2.2 Open pond disadvantages 6

2.3 Closed cultivation systems 8

2.3.1 Closed cultivation system advantages _ 9

2.3.2 Closed cultivation system disadvantages _ 9

2.4 Photobioreactor principles and main components 9 2.5 Photobioreactor system requirements 11

2.5.1 Light requirements _ 11

2.5.2 CO2 addition and pH control 12

2.5.3 O2 removal _ 12

2.5.4 Mixing _ 13

2.5.5 Nutrient requirements _ 13

2.5.6 Temperature control 13

2.5.7 Salinity control 13

2.6 Photobioreactor designs _ 14 2.7 Industrial process requirements _ 15 2.8 Comparison of microalgae production systems _ 15

2.8.1 Comparison of system productivity _ 15

2.8.2 Comparison of estimated production costs 16

2.9 The AlgaePARC pilot facility 17 2.10 Challenges and recommendations _ 20

2.10.1 Industrial microalgae production at Mongstad – initial assessment 20

2.10.2 Photobioreactor development – development of detailed R&D plan _ 20

2.10.3 Establish a pilot facility for industrial microalgae production at Mongstad _ 20

2.10.4 Collaboration with national partners 22

2.10.5 Collaboration with Prof Rene Wijffels and AlgaePARC at Wageningen University 22

CO2 to Bio/WP2 – Algae production

2.1 Introduction

Like plants, algae use the sunlight for the process of photosynthesis. Photosynthesis is an im-

portant biochemical process in which plants, algae, and some bacteria convert the energy of sun-

light to chemical energy. The photosynthetic algae can fix and convert inorganic CO2 into simple

sugars in the Calvin cycle using the captured ligh(figure 1). The simple sugar molecules

are then the starting point for the production of all the other molecules (lipids, proteins, carote-

noids etc) required for the algae to grow.

Fig 1: Simplified scheme of the photosynthesis.

Algae that can grow solely on light energy and inorganic CO2 are called photoautotrophes, while

the algae that obtain their energy from organic compounds and do not depend on light energy

are called heterotrophes. In addition, a group called mixotrophes is algae that can utilize both

these metabolism pathways. There are two main methods of phototrophic algae cultivation (table 1, figure 2):

Closed Photobioreactors

Table 1. Main types of photoptrophic microalgae cultivation systems.

Open cultivation

outdoor system

Shallow big pond

Tanks (circular or rectangular)

Deep (circular or rectangular)

Closed cultivation

covered systems

(pump or airlift)

Vertical column

(bubble- or airlift)

Panels/plates

Microalgae cultivation

Horizontal

Alveolar

vertical y

Fig 2. Main types of photoptrophic microalgae cultivation systems.

2.2 Open pond phototrophic algae production

Until the 1940s micro-algae culture was primarily conducted in the laboratory and in the late

1940s began the exploration of outdoor production systems (Terry & Raymond 1985). The in-

tent was to produce food and feed. Another area of interest was the ability of micro-algae to carry out gas-exchange either as an oxygen producer or a CO2 consumer. Prior do that, open

systems had been used in natural setting such as lakes, ponds and lagoons, in Myanmar, for ex-

ample, where there has been a long tradition of cultivating Spirulina sp. in natural open sys-

tems. Existing lakes, ponds and lagoons can be used as they are or the bottom can be lined with

asphalt, concrete, plastic sheets, rubber, or sprayed material to enhance the cleaning possibili-

ties (figure 3). Alternatively, artificial open systems can be constructed that fit the purpose of pro-duction better. Artificial open systems for microalgae cultivation are often made of concrete, lined

with plastic or tanks made of plastic. The vessels can take the shape of a pond or a tank. Raceway

ponds are the most common type of open cultivation method worldwide (Wolkers et al. 2011).

2.2.1 Open pond advantages

Open systems are recognised for being simple, easy to operate and inexpensive (low capital and

operating costs). They are easy to clean up after cultivation (Ugwu 2008) and low process con-

trol is needed. They are good systems for lower value products with large markets. This technol-ogy exists since the 1950s, so extensive experience exists on operation and engineering of race-

ways (Chisti et al. 2007).

2.2.2 Open pond disadvantages

Open systems suffer from a small illumination surface to volume ratio, so that the limited light pene-

tration only reaches the cells near the surface (Ugwu 2008). This results in a low photosynthetic

efficiency at about 1.5% and a low biomass density of about 0.1-0.2 g/l (Pulz 2001, Norsker et al.

2011, Wolkers 2011). Besides poor productivity, a large ground space is needed for such operations (Ugwu 2008). Also, only short cultivation periods are possible and only a few strains of microalgae

can be cultivated in such systems (Ugwu 2008). Additionally, there is a waste of resources as the

CO2 added to the culture escapes and ends up entering the atmosphere and evaporative losses are

large (Ugwu et al. 2008). The expansion of open systems is only possible in 2D, which is a problem

when space is limited or expensive. Since the system is open, there is a high contamination risk (Pulz

2001). A large amount of algae is needed to initially inoculate the pond and there is only a low level

of control over culture conditions (Ugwu 2008). There is possible contamination by heavy metal and by other algae species (Waltz 2009). Microalgae in open systems are subject to predators

(Waltz 2009) but this may be overcome by combining photobioreactors and open ponds. Algae

strain chosen for open systems must be able to cope with extreme temperature conditions and rain-

fall (Chaumont et al. 1993) and is absolutely weather dependant (Pulz 2001). Only a few algal varie-

ties will cope with this setup (Pulz 2001). The processing product harvesting costs are high because

of large volume of flows with a low cell density and concentration of biomass (Pulz 2001, Chen et al. 2009). It takes 6-8 weeks to produce microalgae again after an interruption (Pulz 2001), so batch

production is more common than continuous production.

CO2 to Bio/WP2 – Algae production

igh ) )for

Fig 3. Examples of open cultivation systems. Both natural and artificial cultivation systems are shown. The source is indicated

under each photo.

2.3 Closed cultivation systems

The disadvantages of open systems have led to the development of closed photobioreactors. In the

1970s microalgae cultivation for the production of methane stared in Europe (Terry & Raymond

1985) and both open and closed systems were investigated and the latter were deemed necessary for

the production of high value products. The design of photobioreactors that maximises productivity,

reduce capital and operating costs is not trivial and many designs have been developed (figure 4).

Fig 4. Examples of closed cultivation system designs. The source is indicated under each photo.

CO2 to Bio/WP2 – Algae production

2.3.1 Closed cultivation system advantages

The advantage of closed systems is the possibility to optimize and control the algal growth more

closely than in open systems. This can result in a much higher biomass yield and density (2-8 g

dryweight/l), and the harvesting process will become more efficient due to small volume of fluid

and the high concentration of algae (Pultz 2001). High algae productivity is possible (Waltz

2009) due to a large surface to volume ratio that increases the photosynthetic efficiency. Prod-

uct standardisation is possible because every element of the production can be controlled: CO2

supply, water supply, temperature, light exposure, culture density, pH, mixing regime. Closed

systems offer good control of CO2 transfer and helps minimal CO2 and culture medium loss. De-

pending on the design, closed systems require less ground area as 3D expansion is possible.

There is less contamination and no external predation on the microalgae. There is an insignifi-

cant dependence on the weather which makes it adequate for many algal species. After a pro-

duction interruption, only 2-4 weeks are needed to have fully functioning system again, and in

case of self-cleaning designs, no production interruption is necessary. Recently-developed self-

cleaning systems allow less fouling than in open and early closed systems and allows continuous

production. Unlike open systems, closed systems can be tuned to avoid photoinhibition. Overall

they are better systems for high value products (such as pharmaceuticals and animal feed). If

genetically modified microalgae were to be produced, the use of closed systems would be abso-

lutely necessary to protect the environment (Waltz 2009).

2.3.2 Closed cultivation system disadvantages

Closed systems are far more complex than open ponds and have therefore higher capital and

operating costs than open systems (Waltz 2009). This is the major disadvantages for closed

cultivation systems compared to open ponds. Productivity and production cost are not always

better than open systems so the end product usually determines the type of production unit cho-

sen. Continuous production requires very fine tuning of all the elements to prevent a collapse of

the culture. There are technical difficulties in sterilizing the culture, which makes it problematic

when targeting a specific product. In order to achieve better photosynthetic efficiency, higher

mixing and installation costs are incurred. There still are difficulties associated with the control

of gradients of pH, oxygen removal, fouling and wall growth which is difficult to control but

some designs have been invented to solve those problems. Additional challenges involve the

hydrodynamic stress experienced by the algae (Chen et al 2009) which might lower production

and can make scale up problematic (Waltz 2009). For very high-value products artificial illumi-

nation is often used (Chisti et al. 2007).

2.4 Photobioreactor principles and main components

All photobioreactors are built in similar fashion: a man-made vessel holds the algal culture

which is composed of water, algae CO2 and nutrients. The design principle of a typical tubular

photobioreactor system is shown in figure 5, with the main components listed in table 2. From

the mixing or feeding vessel where the CO2 and nutrients are added, the algal solution enters a

series of pipes of various designs but which ensure adequate amounts of light, and minimises

hydrodynamic stress for the algae. The photobioreactor itself is used to promote biological

growth by controlling environmental parameters including light. The tubes are made of acrylic and are designed to have light and dark intervals to enhance the growth rate. To ensure the

highest possible productivity of microalgae the following factors have to be controlled in the

photobioreactor: light, nutrients, CO2, mixing, culture density, pH, temperature, and flow rate.

Each of these elements will have to be optimised at each step of the scaling up process. Optimi-

sation will be necessary to avoid culture crashes. The composition of the culture medium is not trivial and differs depending on which alga is be-ing cultivated. After the algae have completed the flow through the pho it passes

Fig 5. Design principle of a tubular photobioreactor system. Most photobioreactors differs in the design of the transparent

vessel, which in this example would be closed loop glasstubes with a diameter between 3-5 cm. The light system can be based on

either natural or artificial light – or a combination of the two.

back to the feeding vessel. As it progresses through the tubes, oxygen sensors continuously

monitor how much oxygen has built up in the plant and this oxygen is to be removed (stripped or

degassed) in connection with the return into the feeding vessel. It is also at this stage that an

optical cell density sensor determines the growth rate over time.

Table 2. The main components of a photobioreactor system.

Main components

General function

1. Light system

Ensure sufficient and effective sunlight

Artificial light source

or artificial light

Avoid too much light that can lead to

Sunlight covering system

2. Optical transmission system

Transparent vessel with high surface to

Different designs exist

volume ratio to allow even light distribu-

3. Gas exchange system

Effective control and removal of

O2 and CO2 sensors

O2 release system

Correct addition of CO2

pH sensor CO2 injection valve

4. Mixing system

To ensure even cell density and distribu-

Recirculation pump

tion of CO2 and nutrients

5. Nutrient system

Continuous addition to ensure optimal

level of nutrients

Nutrient pump Water inlet valve

6. Instrumentation system

Ensuring optimal flow

7. Controlling system

Monitoring of critical parameters and

Conductivity sensor

Temperature sensor PLC Control panel

CO2 to Bio/WP2 – Algae production

When the algal density have reached it optimum, a fraction of the total growth volume is tapped

for harvesting and new water and nutrition is added to replace the harvest volume. In some pho-tobioreactor systems the separated water is passed back to the cultivation system again, while

others discharge the water (supernatant) after the algal biomass have been dewatered. When harvesting algae from a photobioreactor, the dry weight of microalgae is approx. 0.5-3.0 g

of algae per L of media. There are several ways of harvesting. Centrifugation is the most effec-

tive separation method, but is also the most energy demanding dewatering technology. Accord-

ing to Chang et al. 2009 belt harvest system based on advanced membrane or flocculation are the best candidates. Some microalgae may also be induced to flocculate (self-aggregate) by using

coagulants (iron, alum, lime, cellulose, salts, polyacrylamide polymers, surfactants, chitosan,

and other man-made fibres) in order to increase harvesting efficiency. Harvesting and dewater-

ing techniques will be dealt with in another report under this project (WP4 – Biomass).

2.5 Photobioreactor system requirements

The key to success for industrial algal production is to maintain all cultures in the exponential

phase of growth (Lavens and Sorgeloos 1996). The specific growth rate is mainly dependent on

algal species, light intensity and temperature. Furthermore, cell division slows down when nu-

trients, light, pH, CO2 or other physical and chemical factors becomes limiting. In order to

achieve a highly efficient production with maximum growth rates, the optimum culture condi-

tions must be understood and controlled. Optimum culture conditions, in terms of high growth rates, are, however, not necessarily the same as optimum conditions for directing the metabolic pathways – for example towards in-

creased omega-3 production. A compromise between the nutritional quality and growth kinetics

will often have to be considered. For instance, it has been shown that the essential fatty acid,

eicosapentaenoic acid (EPA), increase with decreasing light (Sukenik et al. 1989).

2.5.1 Light requirements

Microalgae are photosynthetic organisms; they assimilate inorganic carbon and transform it to

organic matter. Light is the energy source that drives this reaction. The consideration of the light intensity, photoperiod and spectral quality (see pigments and wavelengths) will contribute to

develop an overall light regime in a photobioreactor. After identifying the type of algae culture to

be grown, it is important to identify the right type of light source with appropriate wavelengths

in order to achieve a high level of photosynthetic efficiency. The light requirement for algae is

dependent upon the major pigments present in the algal cell. Chlorophyll a, b and c ab-

sorb/harvest specific regions in the photosynthetic active region (PAR) of visible light. The biomass density will also affect the light intensity and light penetration through the culture

medium (Richmond, 2004). Optimal cell density is specific to each strain and needs to be main-

tained in order for light intensity and light penetration to remain at optimal levels (Kunjapur,

2010). In practical terms, this will lay restrictions on the design as to decrease the light penetra-

tion pathway to only a few centimeters into the algal culture. In addition to the importance of

the photobioreactor design to lower the surface to volume ratio, the mixing regime is also an

important factor to ensure that the algae receive the right amount of light.

Natural sunlight

Since light is the critical factor to achieve a high biomass and production efficiency by photo-autotroph microalgae, the use of natural daylight as the only light sources will the limit pro-

duction efficiency strongly during the winter months and periods in the spring and autumn. On the other hand, longer days and lower light intensity (less photoinhibition) may prove to

be an advantage in the summer. However, it is reasonable to assume that a full-year large-

scale production at Mongstad must be operated with a combination of daylight and artificial

Another option is to pause the algal production in the darkest months (Nov, Dec, Jan, Feb),

as these months represent only 5% of the total annual solar irradiation in southern Norway. A second option is to use a microalgal species suitable for mixotrophic growth, like Phaeo-

dactylum tricornutum and numerous other species, where the addition of glycerol may con-

tribute to increased EPA levels (Ceron Garcia et al, 2006). Such an exchange can thus be used

to "replace" the photoautotrophic production in low light conditions and to drive the metabo-

lism in a desired direction.

Artificial light

When using an artificial light source to replace or complement natural sunlight, the efficiency

of converting electricity into light must be considered. Light systems used for terrestrial plant

and algae production have often been based on high pressure sodium lamps1, but there is also an ongoing development of low-energy solutions using light-emitting diodes (LED)2. Since

LEDs are the most efficient light source for converting electricity into light with the desired

wavelength, they should be given high priority for use. However, LEDs do not produce light

in a broad white light spectrum which may make it necessary to use a combination of light

sources or combination of LEDs.

Light intensities

The intensity of a light source gives the number of photons that are available for the photo-

synthetic process. The energy associated with photons with a wavelength of 680nm is the en-

ergy level required by chlorophyll a to initiate photosynthesis, and most of the visible light

has sufficient energy to support photosynthesis. However, if the wavelength is small the en-ergy associated with the wavelength is high. Light intensity plays an important role, but the

requirements vary greatly with culture depth and cell density. At high depths and densities

the light intensity must be increased (100-200 µmol m-2 s-1 is often required for large vol-

umes). On the other hand, too high light intensities may result in photoinhibition.

Since naturally grown algae have dark times (nighttime), it is assumed by many researchers

that dark periods are required. Several studies report dark periods from a few milliseconds to

several hours with a positive effect on the photosynthetic effectivity (Jansen, 2003), but there

is no consensus on what an appropriate light:dark cycle or photoperiod should be. Long dark periods generally results in biomass loss as well as a decline in growth rates, because the al-

gae undergo photorespiration and consume oxygen and carbohydrates (Molina et al. 2001,

Merchuk and Wu 2003).

2.5.2 CO2 addition and pH control

The addition of CO2 must be carried out in such a fashion as not to change the pH of the culture

dramatically. The algal cells will assimilate the dissolved CO2 and transform it into organic mat-

ter. However, if the growth rate is low and cells do not remove the CO2 at the expected rate, the increasing level of dissolved CO2 will eventually decrease the pH in the culture medium. The pH

range for most cultured species is between 7 and 9, with the optimum range being 8.2-8.7 (Lav-

ens and Sorgeloos 1996). Culture collapse can be the result when failing to keep an acceptable

pH. The CO2 originating from air ( 0.03%) is limiting growth when bubbled through a dense

culture. Pure CO2 may then be supplemented to the air supply usually at a rate of 1-2% of the

volume of air. CO2 addition furthermore buffers against pH changes. CO2 may also be supple-

mented to the inflow of seawater into the cultures (e.g. Jacobsen et al. 2010).

2.5.3 O2 removal

A high presence of oxygen around algae cells is undesirable. High oxygen concentration results

in photooxidative damage to algal cells, so the oxygen concentrations should be maintained be-

1 Gavita 2 Lumnigro

CO2 to Bio/WP2 – Algae production

low 400% of air saturation value (Chisti, 2007). This will also limit the length of tubular reac-

tors, and challenge scale-up. However, in closed loop systems the culture will be lead through an airlift zone where the accumulated oxygen from photosynthesis is stripped by air/degassed

before the O2 stripped cultivation medium returns to the transparent photobioreactors. Optimi-

zation of the degassing is an important feature to improve the design process.

2.5.4 Mixing

The level of mixing strongly contributes to algal growth in two primary ways;

i) to improve productivity by increasing the frequency of cell exposure to light and dark vol-

umes of the reactor

ii) by increasing mass transfer between the nutrients and cells.

In other words, the mixing of the culture medium attempts to distribute radiation evenly to all

cells in the culture and reduce diffusion barriers around the cells (Jansen, 2003). However, the

level of mixing has to be optimized carefully because high levels of mixing will result in cell

death from shear stress. Shear stress is tolerated differently between algal species and strains,

and should be taken into consideration when selecting the algae to be produced. There are several mixing techniques like low-shear pumps and air-lift systems allowing com-

pressed air to be sparged into the bottom of a reactor, but the optimal solution will depend on

the photobioreactor design principle. Mixing is the most energy demanding factor during closed

system production, and contribute to a significant increase of the operational costs.

2.5.5 Nutrient requirements

Cultures of microalgae must be enriched with nutrients in order to sustain growth. Macronutri-

ents include nitrate, phosphate and silicate. Silicate is mainly used by diatoms, which utilize this compound for production of an external cell covering. Micronutrients consist of various trace

metals (Zn, Co, Cu, Mo, Mn, Fe) and vitamins (thiamine, cyanocobalamin and biotin). Two en-

richment media are commonly used for growth of algae in aquaculture; Walne medium (Laing

1991) and f/2 medium (Guillard 1975). However, the complexity and cost of media excludes

their use for large scale production. Alternative enrichment media for large scale production are

often composed of agriculture-grade rather than laboratory-grade nutrients, and they often con-

tain only the most essential nutrients (Superba Rød3).

2.5.6 Temperature control

Optimum temperature for most microalgae (temperate and sub-tropical species) used is gener-

ally between 18 and 24°C. Many of the cultured species tolerate temperatures between 16-27°C.

Temperatures lower than 16°C will most likely result in slow growth, while temperatures above

35°C will lead to culture collaps (e.g. Acien Fernández et al. 2003). In order to keep stable tem-

peratures, cultures can be cooled down by flow of cold water over the surface of the cultures or

by controlling the air temperature with refrigerated air. The challenge of maintaining both a system that can be used for heating during winter and cooling during summer, can be met by

using a temperature controlled greenhouse – or by keeping a strict control of the temperature in

the feeding vessel.

2.5.7 Salinity control

Marine microalgae are in general tolerant to changes in salinity. In culture, most species grow

best at a salinity that is a bit lower than found in their native habitat (diatoms at 20-25 ‰ and

flagellates at 28-30‰). This can be obtained by diluting sea water with distilled water (Lavens and Sorgeloos 1996).

Fig 6. Examples of different closed reactor design principles. a) conceptual tubular reactor. b) conceptual column reactor. c)

conceptual flat panel reactor. Figures collected from Kunjapur (2010).

2.6 Photobioreactor designs

Beyond the surface area and volume, the unique geometry of a photobioreactor influences the

light distribution, which will, together with the design-dependant mixing method, determine its photosynthestic efficiency and productivity. The design of the transparent cultivation vessel dif-

fers between the three main types of closed photobioreactor types, as shown in figure 6. Each of

the reactor types have their benefits and disadvantages (table 3), and it is not possible to say

which system will be the best option in general.

There are several factors that will determine what the best PBR solution is for a particular pur-

The product - which should be on the market (value, volume, market development, side

The algae - which are best to produce this product (and possibly by-product).

The conditions of production - solar / light, temperature, availability of CO2, nutrients,

batch versus continuous, limiting factors

The volume - requirements for scale and production

Maintenance - convenient in FHT cleaning, material life, etc.

Costs - both capital costs and operating costs will be decisive.

With this background, the whole production system had to be tailored for a given product, the

comparison of different PBR system must be part of a pilot or planning stage.

Table 3. Typical advantages and disadvantages of the three main types of closed photobioreactors (Kunjapur, 2010).

Reactor type

Typical advantages

Typical disadvantages

Flat panels

• shortest oxygen path

• low photosynthetic efficiency

• low power consumption

• shear damage from aeration

• high volumetric biomass density

• oxygen accumulation

• photoinhibition

• most land use

Vertical

• greatest gas exchange

• support costs

• best exposure to light/dark cycles

• least land use

• high photosynthetic efficiency

CO2 to Bio/WP2 – Algae production

2.7 Industrial process requirements

Algae@work4 recognizes ten essential requirements for algal cultivation to become a viable

mode of CCR (carbon capture and recycle). A high degree of control yet flexibility is required in

modes of cultivation and harvesting. Uninterrupted production is necessary over long periods of

time and the photobioreactors must be designed to ensure high productivity, profitability and

industrial relevance. The production cannot be stopped by infections (bacteria, virus and other

microalgae) and those threats to production must be managed successfully to ensure a steady supply of the product. Photobioreactors must often be cooled or heated and the efficient man-

agement of water and energy must be achieved. Once the production has been started and is

successful the operations must be scaled up in a sustainable way, and there must be enough

space to ensure the possibility of expansion. Crop value, length of productive season and indus-

trial reliability must be obtained through high technological advances in photobioreactors de-

velopments. Cellular re-suspension must be obtained to ensure access of algae to nutrients, limit cell death and bacterial growth leading to system crashes. Bacterial biofilms growing on the

pipes of the photobioreactors can reduce the access of algae to light and also start bacterial in-

fections. Biofilms management must thus be carried out with high efficiency. The only manner

in which the production of microalgae will be of significance in CCR, is to ensure high industrial

efficiency as many upstream and downstream processes will depend on it when operating at full

scale. The planning of a microalgae production for the purpose of CCR must fall in line with the

goal of regulatory agencies, framework, funding agencies, lending banks etc to be politically de-ployable.

2.8 Comparison of microalgae production systems

The comparison of microalgal production system described in the literature is not an easy task,

because the cultures have been grown under slight different conditions. Several condition pa-rameters will have an effect on the productivity – not only the system design alone. The present

photobioreactor designs have not reached its full optimization potential wrt increasing the pho-

tosynthetic efficiency - defined as the fraction of light energy converted into chemical energy

during photosynthesis (theoretic maximum at 9%). The main focus is to keep costs and energy

demand low during production and increase the photosynthetic efficiency and biomass yield. However, the overall optimization potential of the photosynthetic efficiency lies not only on the

production systems, but there is also a promising potential in the screening and development of production-efficient algal strains, in combination with exploiting physiological properties

through metabolic stress until harvest.

2.8.1 Comparison of system productivity

When searching the literature about the productivity of various microalgae production systems

the difficulty is to obtain estimates in the same units; a summary is provided of the most com-

monly used units to measure production capacity per area (Table 4). Open raceway ponds can

have productivities as low as natural lakes, but as high as flat horizontal photobioreactors. Among the closed photobioreactors vertical columns and horizontal tubular photobioreactors

score the highest.

However, one should keep in mind that a true comparison should be performed side-by-side

under similar conditions in order to be valid. Different growth conditions will affect the out-

come, as will the production scale at which the cultivation studies have been performed. An increasing light intensity will increase the productivity up to a certain point where oversatu-ration and photoinhibition occurs. Cuaresma et al (2011) showed how the productivity increased

with a vertical orientation compared to a horizontal system under light conditions simulating

daily light cycles in southern Spain. The strong irradiance at 1800 umol photons m-2 s-1 on the

4 A2BE Carbon Capture

Table 4. Production efficiency and capacity of various cultivation systems.

Cultivation type

Production capacity

References

efficiency (PE)

ton dry weight/ha/year

Raceway pond

horizontal

Vertical column

Flat panel

horizontal reactor could not be exploited properly due to oversaturation, but with a vertical position-

ing the incident light were reduced to a level (400 umol photons m-2 s-1) where the productivity was

high. This may not be the case for Norway where solar irradiation may not have to be diluted.

2.8.2 Comparison of estimated production costs

The research group of Rene Wijffels at AlgaePARC (see next section) focus strongly on the eco-

nomics of microalgal production. In a recent study, Norsker and co-workers compared the pro-

duction costs of three photobioreactor systems; open pond, tubular bioreactors and flat panel

bioreactors (Norsker et al, 2011). The photosynthetic efficiency and productivity were signifi-

cantly higher for the flat panel bioreactors, with values about 30% higher than those of the tubu-

lar system (table 4). However, while the flat panels were more productive, this production system also proved to be

more costly compared to tubular bioreactors when calculating the production costs (figure 7).

The critical cost contributions (underlined) for both reactor systems are the mixing instrumen-

tation to ensure mass transfer and oxygen removal. While the tubular systems use low-shear

pumps, the flat panels use airflow with an energy demanding screw blower. The production

costs for algal biomass produced with tubular bioreactors was calculated at 4.16 € per kg dry

weight, compared to the flat panels at 5.96 per kg dry weight (table 5).

Fig 7. Unit biomass production cost (in cts, eurocents). Based on various capital and operating cost elements for raceway

ponds, tubular photobioreactors and flat panel photobioreactors. Table view from Norsker et al (2011).

CO2 to Bio/WP2 – Algae production

Table 5. Sensitivity analysis. Biomass cost in € per kg/ with different scenarios (100 ha plant).Source: Norsker et al. (2011).

Flat panel

(€/kg DW)

(€/kg DW)

(€/kg DW)

1. Base case

2. Bonaire location

3. Minimum mixing

4. CO2 is free

(in addition 3)

5. Medium is free

(in addition to 4)

6. PE increase 60%

(in addition to 5)

7. Bonaire location

(in addition to 6)

Norsker and co-workers also performed a sensitivity analysis of the effects of ongoing and fore-seen improvements regarding reduction of mixing costs, improvement of irradiation and photo-synthetic efficiency, free CO2 and reduction of nutrient costs (table 5, points 3-6). These are pro-

duction system improvements considered realistic by the authors in short term (about 10 years

from now). Under these premises, the production costs for algal biomass produced in outside

tubular photobioreactors in the Netherlands was calculated to 1.43 € per kg dry weight, and 1.44

for production in flat panels. In addition, the study also investigated how the light conditions and productivity in the Nether-lands compared with microalgal production at a tropical site (Bonaire at the Dutch Antilles),

and how that would affect the biomass production costs. The simulated production in a tropical

site with much sunlight would drive this down to 0.70 € per kg dry weight – about half the cost

compared to a production relying on natural sunlight in the Netherlands. This is a good indica-

tion of what impact light conditions have. It may also indicate the potential benefits of in-

creased productivity when using optimized artificial light systems, and how it can affect the final

biomass cost level. The technology development will keep driving the productivity up and production cost down -

and as the maturity level is not reached at the moment, it is too early to estimate the area re-

quirements for a given product volume. However, is important to keep working with the existing

production systems and participate in technology drive and system development.

2.9 The AlgaePARC pilot facility

The cultivation capacity of microalgae is relatively small and inefficient and there experience

with large-scale, cost-effective production. Therefore, Wageningen UR, together with industry

partners investigate the optimization of algae production in outdoor systems at the recently es-

tablish Algae Production And Research Centre (AlgaePARC). At the AlgaePARC facility teams of

scientists study various aspects of algae cultivation. To make the production of algae competitive

at the bulk products market a strong economic and technological boost is needed5.

5 Source: AlgaePA

Below is an excerpt from the report "Microalgae: the green gold of the future?" describing the

research aims and activities planned at AlgaePARC6:

"Research in AlgaePARC The production costs of algae cultivation must be decreased drastically, to

one-tenth of the current level. Increasing the photosynthetic efficiency is one of the most important stipulations. This can be achieved by applying improved

reactor designs and use more efficient algae. In addition, a substantial saving on nutrients becomes possible by making use of waste and residual flows and

recycling of these nutrients. Furthermore, a considerable reduction of energy

consumption can be reached by means of mixing the algae soup less and the use of energy-efficient pumps. Also better harvest and downstream

processing methods (biorefining) can significantly contribute to reduce costs, but also to improve the final product.

For example, conventional methods to isolate oil from algae cells are quite harsh, i.e. high pressure and temperature disrupt the cell wall causing the oil

to be released. However, because of the harsh conditions the proteins will

denature resulting in a lower value of the biomass. Therefore, mild biorefinery techniques to isolate the algae products are necessary. Finally, shifting the

cultivation to sunnier locations might contribute to a higher efficiency and substantial cost reduction. AlgaePARC must be a bridge between small-scale laboratory research and large-scale production. The research team will verify the results of the small scale

experiments on larger scale in AlgaePARC. In addition, the team will

compare the four major algae cultivation systems regarding costs, growth efficiency and sustainability. An open pond will serve as reference as it is the most common cultivation system worldwide. The researchers will compare the performance of closed

systems, for example, horizontal layers, vertically transparent tubes, flat

plates and a raceway pond, throughout the year. Each cultivation system has specific advantages and disadvantages, but the ultimate goal is maximum

production of high quality algae at the lowest possible price throughout the year. Besides the type of cultivation system, it is also important to design the cultivation conditions in such a way that an optimal production of the desired

algae product, e.g. oil, is obtained. Traditionally the algae are grown until a

certain density. Subsequently they are starved from nutrients; the algae stop growing and start to produce more oil. Usually these two processes are run in

sequence: first the amount of biomass is increased rapidly, and then the oil starts to accumulate slowly. In AlgaePARC the goal is to design a process

aimed at the optimal production of certain metabolites (such as oil or starch) and not of biomass. Because production conditions will continuously change,

production strategies that are aimed at a constant quality of the final product

will be designed, by means of measuring and controlling.

The test facility is just a start of what should become the leading algae testing

centre of Europe. Particularly research and development of methods aimed at making specific end products will be further expanded in the coming years.

Not only reactor design will get attention, but also the search for new algae

species and improvement of existing algae strains by genetic modification.

In addition, there will be a lot of attention for improved biorefinery methods

and sustainability of the entire production chain. Wageningen UR wants to do innovative research on algae cultivation technologies in collaboration with

6 Wolkers et al, (2011)

CO2 to Bio/WP2 – Algae production

other knowledge institutes and industry within the Netherlands and abroad.

This can be both fundamental and applied research. It is also important that

the research on algae is an inspiring learning environment for students. AlgaePARC will be a success if after 5 years we:

Are able to make a good comparison of different production systems

based on the following parameters: photosynthetic efficiency, volumetric productivity, energy use, use of nutrients and water availability,

robustness and scalability

Have achieved and maintained throughout the year, a photosynthetic

efficiency on sunlight outdoors of 5%

Have developed an improved reactor concept and/or process strategy in

which the production costs and energy needs are lower compared to traditional systems

Have obtained sufficient basic information for the design of a large-scale

production facility

Worldwide research on algae is emerging. Companies and governments invest a lot in algae research programmes. In the United States there are large

projects in the field of genetic modification of microalgae, China does a lot in

bioinformatics of algae and in Europe scientists will realise the first demonstration facilities within some years. Wageningen UR distinguishes itself from these activities by working in an integrated, multidisciplinary manner on the improvement of the technology.

This means working at the same time on the improvement of species, on development of efficient production methods and on biorefinery- and

sustainability aspects."

Fig 8. Outdoor facilities at the AlgaePARC seen from the NW. The different pilot production systems are compared side-by-side.

From the left; the vertical tubular reactors, the horizontal tubular reactor, a flat panel system shown in the front and the reference

raceway pond in the far right. Source

2.10 Challenges and recommendations

The main challenge is to reduce investment and production costs by lowering the energy de-

manding steps and increase the photosynthetic efficiency and biomass yield. However, it is important to stress that the overall optimization potential of the photosynthetic

efficiency lies not only on the production systems described in this WP-report. There is also a

promising potential in the screening and development of production-efficient algal strains, in

combination with exploiting physiological properties through metabolic stress until harvest (WP3). In addition, the downstream processing and logistics solutions along the value chain

through to the finished product will be crucial for the cost picture (WP4).

Based on this, some recommendations on how to meet the challenges at this stage is given below.

2.10.1 Industrial microalgae production at Mongstad – initial assessment

Our initial technical assessment is that Mongstad is a suitable location for industrial microalgae

production. Based on this report – together with the reports on WP3 and WP4, some recom-

mendations can be made at this stage for the pilot facility.

Recommendations:

The production should be based on closed photobioreactors.

The best performance and low-cost tubular and flat panel reactors should be compared.

The production area should be covered by a greenhouse.

The production areas should be temperature controlled.

The production should be based on artificial light as a supplement to natural sunlight.

The production area should be flexible to allow development and comparison of photobioreactors.

The pilot facility should establish a photobioreactor similar to an AlgaePARC type as reference.

A water treatment facility is required.