Cover.doc

ELECTROSPINNING OF POLY(VINYL ALCOHOL)/CHITOSAN FIBERS

FOR WOUND DRESSING APPLICATIONS

MS.SUNISA PANBOON

A THESIS SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS

FOR THE DEGREE OF MASTER OF SCIENCE (MATERIALS SCIENCE)

DEPARTMENT OF INDUSTRIAL CHEMISTRY

GRADUATE COLLEGE

KING MONGKUT'S INSTITUTE OF TECHNOLOGY NORTH BANGKOK

ACADEMIC YEAR 2005

ISBN 974-19-0476-2

COPYRIGHT OF KING MONGKUT'S INSTITUTE OF TECHNOLOGY NORTH BANGKOK

: Ms. Sunisa Panboon

Thesis Title : Electrospinning of Poly(vinyl alcohol)/Chitosan Fibers for

Wound Dressing Applications

Major field : Materials Science

King Mongkut's Institute of Technology North Bangkok

Thesis Advisors : Associate Professor Narumol Kreua-ongarjnukool

Dr. Ratthapol Rangkupan

Academic Year : 2005

Abstract

In this study, ultrafine fibers of poly(vinyl alcohol) blend with chitosan were

successfully prepared by electrospinning process. The effect of processing parameter and solution properties (i.e. applied electrical potential, collection distance, concentration of chitosan solution and weight ratio of PVA solution/chitosan solution) on processability and morphological appearance of the obtained fibers were investigated. Results from FTIR and DSC confirmed that the electrospun fiber consists of PVA and chitosan. Morphological study of the fibers was carried out with the scanning electron microscope. It was found that as the ratio of chitosan solution in blend solution increased, the average fiber diameter was decreased. While, increasing chitosan solution from 2wt% to 3wt%, resulting in smaller fiber diameter with higher number of beads at the same mixing ratio. The results also showed that both collection distance and applied electrical potential had slight tendency toward decreasing fiber diameter as both parameters increased. It can be said that both parameters in electrospinning had no significant effect to fiber diameters of 10wt%PVA/2wt%chitosan fibers at ratios of 60/40 and 50/50 w/w. Furthermore, blend solution of 10wt%PVA/2wt%chitosan in 60/40 and 50/50 mixing ratio were tested in antimicrobial assessment with Escherichia coli (E.coli) bacteria by agar medium assay and scanning electron micrographs of electrospun fiber samples tested with E.coli were observed. The result strongly indicated an inhibition of E.coli growth in these fibers, and elucidate potential use of such system in biomedical application such as wound dressing.

(Total 87 Pages)

: นางสาวสุณิสา ปานบุญ

: วัสดุศาสตร

ดร.รัฐพล รังกุพันธุ

I would like to express my sincere gratitude to Associate Professor Narumol

Kreua-ongarjnukool, Dr.Ratthapol Rangkupan, Associate Professor Dr.Pitt Supaphol and Dr.Rath Pichyangkura for their helpful guidance, suggestion and encouragement throughout this study. I am also indebted to Metallurgy and Materials Science Research Institute Chulalongkorn University and the Petroleum and Petrochemical College Chulalongkorn University for providing the valuable equipments. Moreover, I would like to thank the Scientific and Technological Research Equipment Center, Chulalongkorn University for recording scanning electron micrographs, Fourier-transform Infrared Spectra and Differential Scanning Calorimetry thermograms. In addition, cordial and sincere thank is extended to all staffs at both Metallurgy and Materials Science Research Institute, Chulalongkorn University and the Petroleum and Petrochemical College, Chulalongkorn University. Moreover, special thank is also extended to both graduated students and Ph.D.student at the Biochemistry Department, Faculty of Science, Chulalongkorn University for kindly help in instrument training for antimicrobial testing to carry on my thesis work Also, I would like to thank to my family, my friends and the staff of the Industrial Chemistry Department, Faculty of Applied Science, King Mongkut's Institute of Technology North Bangkok for their helpful suggestion and valuable assistance throughout the entire research. Finally, I would like to thank the Graduate College of King Mongkut's Institute of Technology North Bangkok and also Nanopolymer Scheme of Chulalongkorn University for providing financial support from the research fund.

TABLE OF CONTENTS

Abstract (in English)

Abstract (in Thai)

Chapter 1. Introduction

1.1 Objectives of this research

1.2 Scopes of this research

1.3 Benefits of this research

Chapter 2. Background and Theory

2.1 Electrospinning process

2.2 Biopolymers

2.2.1 Chitin/Chitosan

2.2.2 Poly(vinyl alcohol) (PVA)

2.2.3 Polyglycolide (PGA)

2.2.4 Polylactide (PLA)

2.2.5 Poly (lactide-co-glycolide)

2.2.6 Poly(ε-caprolactone)

2.3 Microbiology

2.3.1 Escherichia coli bacteria

2.3.2 The requirements for microbial growth

2.3.3 Culture Media for the Growth of Bacteria

2.3.4 The growth curve

2.4 Wound healing and wound dressing

2.4.3 Treatment

Chapter 3. Experimental

3.2 Chemical reagents

3.3 Experimental methods

3.3.1 Preparation of PVA/chitosan solutions

3.3.2 Electrospinning

3.3.3 Parameters of electrospinning process

3.3.4 Characterization

Chapter 4. Results and Discussion

4.1 Properties of PVA/chitosan solutions

4.1.1 Viscosity of solutions

4.1.2 Conductivity of solutions

TABLE OF CONTENTS (CONTINUED)

4.2 Electrospun PVA/chitosan fibers

4.3 Characterization of electrospun fibers

4.3.1 Fourier-transform infrared spectroscopy (FT-IR)

4.3.2 Differential scanning calorimetry (DSC)

4.4 Parameters of electrospinning process

4.4.1 Effect of concentration of chitosan in PVA/chitosan solution

4.4.2 Effect of collection distance

4.4.3 Effect of applied electrical potential

4.5 Antimicrobial assessment

Chapter 5. Conclusions and Suggestions

Appendix A FTIR spectra of PVA/chitosan electrospun fibers

Appendix B DSC thermograms of electrospun PVA fibers, chitosan, and

PVA/chitosan electrospun

Appendix C Range of fiber diameters of PVA electrospun, 10wt%PVA/2wt%chitosan with ratios ranging from 30/70 to 90/10, and 10wt%PVA/3wt%chitosan with ratios ranging from 50/50 to 90/10, respectively

Appendix D Range of fiber diameters of 10wt%PVA/2wt%chitosan with

ratios as 60/40 and 50/50 at various collection distances

Appendix E Range of fiber diameters of 10wt%PVA/2wt%chitosan with

ratios as 60/40 and 50/50 at various applied electrical potentials

Appendix F Antimicrobial assessment

a) Estimating bacterial numbers by indirect methods Turbidity

b) Preparation of microbial concentration with 105 CFU/ml

LIST OF TABLES

2-1 Polymer solvent systems for electrospinning

2-2 Antimicrobial chitosan

2-3 Minimum, maximum and optimum temperature for growth of certain bacteria and archaea

2-4 Terms used to describe organisms in relation to temperature requirement for growth

2-5 Major elements, their sources and functions in bacterial cells

2-6 Common vitamins required in the nutrition of certain bacteria

2-7 Terms used to describe O2 relations of microorganisms

4-1 Polymer weight (g) in blended solutions and weight fraction of PVA/CH in various PVA-to-CH weight ratios

4-2 Properties of blended solutions with concentrations of 10 wt%PVA and 2 wt% chitosan

4-3 Properties of blended solutions with concentrations of 10 wt% PVA and 3 wt% chitosan

4-4 The effect of ratio of PVA to chitosan in 10wt%PVA/2wt%chitosan solution on morphology of electrospun fibers

4-5 The effect of ratio of PVA to chitosan in 10wt%PVA/3wt%chitosan solution on morphology of electrospun fibers

4-6 Fiber diameters (nm) of PVA/chitosan fibers with various ratios

4-7 The effect of collection distance on morphology of 10 wt%PVA / 2 wt%chitosan with ratio as 60/40 electrospun fiber

4-8 The effect of collection distance on morphology of 10 wt%PVA / 2 wt%chitosan with ratio as 50/50 electrospun fiber

4-9 The effect of collection distance on fiber diameters with the ratio of PVA to chitosan as 60/40 and 50/50

4-10 The effect of applied electrical potential on morphology of 10 wt%PVA / 2 wt%chitosan with ratio as 60/40 electrospun fiber

4-11 The effect of applied electrical potential on morphology of 10 wt%PVA / 2 wt%chitosan with ratio as 50/50 electrospun fiber

4-12 The effect of applied electrical potential on fiber diameters with the ratio of PVA to chitosan as 60/40 and 50/50

LIST OF FIGURES

2-1 Schematic of the experimental set-up

2-2 Chemical structure of chitin

2-3 Chemical structure of chitosan

2-4 Hydrolysis of poly(vinyl acetate)

2-5 Chemical structure of poly(lactide-co-glycolide)

2-6 Chemical structure of poly(ε-caprolactone)

2-7 The morphology of Escherichia coli at x10,000 magnification

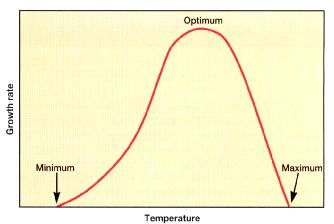

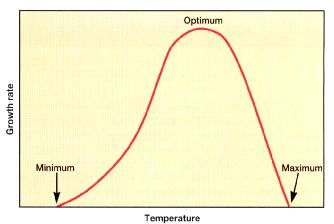

2-8 The effect of temperature on growth rate

2-9 Growth rate versus temperature for five environmental classes of procaryotes

2-10 Growth rate versus pH for three environmental classes of prokaryotes

2-11 Plasmolysis

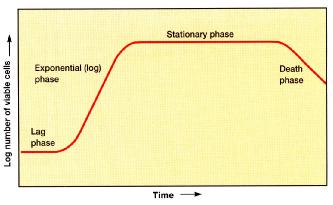

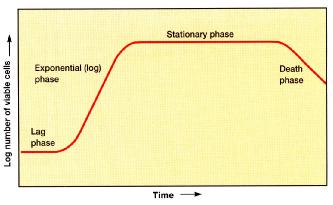

2-12 Microbial growth curve

3-1 Electrospinning instrument

3-3 Inoculating loop and inoculating needle

3-4 Streak plate patterns

4-1 Viscosity of blend solution of 10wt% PVA and chitosan at concentration of 2wt% and 3wt% as a function of the

weight ratio of chitosan solution

4-2 Conductivity of blend solution of 10wt% PVA and chitosan at concentration of 2wt% and 3wt% as a function of the weight ratio of chitosan solution

4-3 FTIR spectra of electrospun PVA fibers

4-4 FTIR spectra of chitosan powder

4-5 Comparison of FTIR spectra of electrospun PVA/chitosan fibers

in various PVA-to-chitosan weight ratios

4-6 Comparison of DSC thermogram of PVA/chitosan electrospun with various ratios

4-7 Scanning electron micrographs (original magnification 10x103) of electrospun 10wt%PVA blended with 2 wt% chitosan fibers with various ratios of PVA to chitosan

4-8 Scanning electron micrographs (original magnification 10x103) of electrospun 10 wt% PVA blended with 3 wt% chitosan fibers with different weight ratios of PVA to chitosan 42 4-9 Scanning electron micrographs of electrospun 10wt% PVA fibers (original magnification 10x103) 43 4-10 The average of fiber diameter as function of ratios of chitosan in blend with concentration of chitosan as 2wt% and 3wt% 44

LIST OF FIGURES (CONTINUED)

4-11 Scanning electron micrographs of electrospun 10 wt% PVA

blended with 2 wt% chitosan fibers in the weight ratio of PVA to chitosan as 60/40 with different collection distances while the applied electrical potential is fixed as 15 kV

4-12 Scanning electron micrographs of electrospun 10 wt% PVA blended with 2 wt% chitosan fibers in the weight ratio of PVA to chitosan as 50/50 with different collection distances while the voltage is fixed as 15 kV

4-13 The effect of collection distance on fiber diameter with the ratio of PVA to chitosan as 60/40 and 50/50

4-14 Scanning electron micrographs of electrospun 10 wt% PVA

blended with 2 wt% chitosan fibers in the weight ratio of PVA to chitosan as 60/40 with different voltages while

the collection distance is fixed as 10 cm

4-15 Scanning electron micrographs of electrospun 10 wt% PVA

blended with 2 wt% chitosan fibers in the weight ratio of PVA

to chitosan as 50/50 with different voltages while the collection distance is fixed as 10 cm

4-16 The effect of applied applied electrical potentials on fiber diameter

with the ratio of PVA to chitosan as 60/40 and 50/50

4-17 Agar plate diffusion method

4-18 The structure of the E.coli bacterium

4-19 Scanning electron micrographs of the growth of Escherichia.coli (E.coli) for 4 hours incubation time on the following samples in antimicrobial test (original magnification 5x103)

A-1 FTIR spectra of PVA/chitosan electrospun with ratio of

A-2 FTIR spectra of PVA/chitosan electrospun with ratio of blend as 80/20

A-3 FTIR spectra of PVA/chitosan electrospun with ratio of blend as 70/30

A-4 FTIR spectra of PVA/chitosan electrospun with ratio of

A-5 FTIR spectra of PVA/chitosan electrospun with ratio of blend as 50/50

B-1 DSC thermogram of electrospun PVA fibers

B-2 DSC thermogram of chitosan powder

LIST OF FIGURES (CONTINUED)

B-3 DSC thermogram of PVA/chitosan electrospun with ratio of blend as 90/10

B-4 DSC thermogram of PVA/chitosan electrospun with ratio of blend as 80/20

B-5 DSC thermogram of PVA/chitosan electrospun with ratio of blend as 70/30

B-6 DSC thermogram of PVA/chitosan electrospun with ratio of blend as 60/40

B-7 DSC thermogram of PVA/chitosan electrospun with ratio of blend as 50/50

C-1 Range of fiber diameters of PVA electrospun

C-2 Range of fiber diameters of PVA/2wt%chitosan with ratio as 30/70

C-3 Range of fiber diameters of PVA/2wt%chitosan with ratio as 40/60

C-4 Range of fiber diameters of PVA/2wt%chitosan with ratio as 50/50

C-5 Range of fiber diameters of PVA/2wt%chitosan with ratio as 60/40

C-6 Range of fiber diameters of PVA/2wt%chitosan with ratio as 70/30

C-7 Range of fiber diameters of PVA/2wt%chitosan with ratio as 80/20

C-8 Range of fiber diameters of PVA/2wt%chitosan with ratio as 90/10

C-9 Range of fiber diameters of PVA/3wt%chitosan with ratio as 50/50

C-10 Range of fiber diameters of PVA/3wt%chitosan with ratio as 60/40

C-11 Range of fiber diameters of PVA/3wt%chitosan with ratio as 70/30

C-12 Range of fiber diameters of PVA/3wt%chitosan with ratio as 80/20

C-13 Range of fiber diameters of PVA/3wt%chitosan with ratio as 90/10

D-1 Range of fiber diameters of PVA/chitosan with ratio as 60/40 at 6 cm collection distance

D-2 Range of fiber diameters of PVA/chitosan with ratio as 60/40 at 8 cm collection distance

D-3 Range of fiber diameters of PVA/chitosan with ratio as 60/40 at 10 cm collection distance

D-4 Range of fiber diameters of PVA/chitosan with ratio as 60/40 at 12 cm collection distance

D-5 Range of fiber diameters of PVA/chitosan with ratio as 50/50 at 6 cm collection distance

D-6 Range of fiber diameters of PVA/chitosan with ratio as 50/50 at 8 cm collection distance

D-7 Range of fiber diameters of PVA/chitosan with ratio as 50/50 at 10 cm collection distance

D-8 Range of fiber diameters of PVA/chitosan with ratio as 50/50 at 12 cm collection distance

LIST OF FIGURES (CONTINUED)

E-1 Range of fiber diameters of PVA/chitosan with ratio as 60/40 at 10 kV applied electrical potential

E-2 Range of fiber diameters of PVA/chitosan with ratio as 60/40 at 13 kV applied electrical potential

E-3 Range of fiber diameters of PVA/chitosan with ratio as 60/40 at 15 kV applied electrical potential

E-4 Range of fiber diameters of PVA/chitosan with ratio as 60/40 at 18 kV applied electrical potential

E-5 Range of fiber diameters of PVA/chitosan with ratio as 60/40 at 20 kV applied electrical potential

E-6 Range of fiber diameters of PVA/chitosan with ratio as 50/50 at 10 kV applied electrical potential

E-7 Range of fiber diameters of PVA/chitosan with ratio as 50/50 at 13 kV applied electrical potential

E-8 Range of fiber diameters of PVA/chitosan with ratio as 50/50 at 15 kV applied electrical potential

E-9 Range of fiber diameters of PVA/chitosan with ratio as 50/50

at 18 kV applied electrical potential

E-10 Range of fiber diameters of PVA/chitosan with ratio as 50/50 at 20 kV applied electrical potential

F-1 Turbidity estimation of bacterial numbers

Chapter 1

The electrospinning technique allows the preparation of ultrafine fibers with

diameters ranging from micron to nanoscale fibrous materials. The electrospinning is a novel and efficient fabrication process that produced electrospun fibers through the action of an external electric field to create an electrically charged jet of polymer solution or melt with simultaneous rapid evaporation of the solvent and leave a polymer fiber. The advantages of electrospinning process are simple equipment and cost effective process whereas requiring a long time to obtain enough fibers. The morphology of fibers depends on the process parameters, including the solution concentration, applied electric field strength, deposition distance, deposition time and flow rate. Moreover, system parameters of this technique are molecular weight, molecular weight distribution and architecture of the polymer e.g. branched or linear chain, including solution properties such as viscosity, conductivity and surface tension. Also, the ambient parameters are temperature, humidity, air velocity in chamber and motion of target screen. Typically, electrospinning is applicable to a wide range of polymers, i.e. polyolefin, polyamides, polyester, aramid, acrylic as well as biopolymers like proteins, DNA, polypeptides and polysaccharides.

Due to electrospun fibers have a large specific surface area, light weight and

high porosity, they are of interests in a wide variety of applications including semi-permeable membranes, nanocomposites, filters, protection clothing and biomedical applications such as tissue templates, medical prostheses, artificial organ, wound dressings and drug delivery systems. Especially, for wound dressing applications biopolymers

polycaprolactone, poly(ethylene oxide) and poly(vinyl alcohol):(PVA) were often selected because of excellent biocompatibility and bioresorbable materials.

Therefore, this work focused on preparation of PVA/chitosan fibers for wound

dressing applications. Chitosan has distinct characterisations such as biodegradability, biocompatibility, nontoxicity, acceleration in growth of fibroblast cell for wound healing, and antimicrobial activity. In order to obtain the wound dressing with antibacterial property, chitosan was selected to blend with PVA to produce electrospun fibers due to PVA can be conveniently electrospun while alone chitosan fiber was not formed.

1.1 Objectives of this thesis

1.1.1 To prepare fibers from blended solutions of PVA and chitosan by

electrospinning technique and study the influence of the processing parameters on

fiber morphology.

1.1.2 To assess the possibility to use the PVA/chitosan fiber mats in wound

dressing application by testing their antimicrobial activity.

1.2 Scopes of this thesis

1.2.1 To characterize the properties of blended PVA/chitosan solutions such as

viscosity and conductivity, to prepare electrospun PVA/chitosan fibers by

electrospinning, and to characterize PVA/chitosan fibers by FTIR and DSC techniques.

1.2.2 To study the effect of processing parameters such as chitosan

concentration, PVA-to-chitosan weight ratio, applied electrical potential, and

collection distance on fiber morphology.

1.2.3 To study antimicrobial activity of electrospun PVA/chitosan fibers.

1.3 Benefits of this thesis

1.3.1 Able to understand electrospinning technique for fiber preparation.

1.3.2 Able to prepare PVA/chitosan fibers by electrospinning.

1.3.3 Able to apply PVA/chitosan fibers to wound dressing materials with

antimicrobial property.

Chapter 2

Background and Theory

2.1 Electrospinning process

Electrospinning is a unique method to prepare electrospun fibers with diameters

in the range from micrometers to nanometers that depends on the kinds of polymer and processing conditions.

FIGURE 2-1 Schematic of the experimental set-up [1]

The electrospinning experimental is represented in FIGURE 2-1 above. There

are mainly three components to fulfill the process as follows: a high voltage power supplier, a capillary tube or syringe with a pipette or needle of small diameter, and a metal collecting screen. One electrode is placed into the spinning solution and the other attached to the collector in which the collector mostly is simply grounded. A high voltage is used to induce charges migration in solution to aggregate at the end of the capillary tube. When the intensity of the electric field is increased, the hemispherical surface of the fluid at the tip of the capillary tube elongates to form a conical shape known as the Taylor cone. Further increasing the electric field is used to reach a critical value in which the repulsive electrostatic force overcomes the surface tension of fluid, the charged jet of the fluid is ejected from the tip of the Taylor cone. The discharged polymer solution jet undergoes an stability and elongation process, which allows the jet to become very long and thin. Meanwhile, the solvent evaporates, leaving behind a charged electrospun fiber called nonwoven. It can be said that the electrospinning process has three stages as follows: Firstly, the jet initiation and the extension of the jet along a straight line. Secondly, the growth of a bending instability and the further elongation of the jet, which allows the jet to become very long and thin while it follows a looping and spiraling path. Finally, the solidification of the jet into electrospun fibers [2].

The polymer is usually dissolved in suitable solvent and spun from solution.

Electrospun fibers in the range of 10 to 2000 nm diameter can be achieved by choosing the appropriate polymer solvent system. TABLE 2-1 represents list of some of polymer solvent systems used in electrospinning.

TABLE 2-1 Polymer solvent systems for electrospinning

Solvents

Nylon 6 and nylon 66

Polyacrylonitrile

Dimethyl formaldehyde

Trifluoroacetic acid/Dimethyl chloride

Nylon-6-co-polyamide

Polybenzimidazole

Dimethyl acetamide

Electrospun fibers exhibit special properties mainly due to extremely high

surface to weight ratio compared to conventional nonwovens. Low density, large surface area to mass, high pore volume, tight pore size, flexibility in surface functionalities, and superior mechanical performance make the electrospun fiber nonwoven appropriate for a wide range of applications.

Electrospun fibers have significant applications in the area of filtration since

their surface area is substantially greater and have smaller micropores than melt blown (MB) webs. High porous structure with high surface area makes them ideally suited for many filtration applications. Electrospun fibers are ideally suited for filtering submicron particles from air or water. As a result of a light weight and breathable fabric, which is permeable to both air and water vapor, insoluble in all solvents and highly reactive with nerve gases and other deadly chemical agents, nonwoven products have potential uses in a wide range of filtration applications such as aerosol filters, facemasks, and protective clothing. Electrospun fibers are also used in biomedical applications, which include, drug and gene delivery, artificial blood vessels, artificial organs, and medical facemasks. Electrospun fibers and webs are capable of delivering medicines directly to internal tissues. Electrospun fibers can be also used as varieties of medical applications such as wound dressing or sutures that ultimately dissolve into body. Nonwoven nanofibrous membrane mats for wound dressing usually have pore sizes ranging from 500 nm to 1 µm, small enough to protect the wound from bacterial penetration via aerosol particle capturing mechanisms and also high surface area of 5-100 m2/g is extremely efficient for fluid absorption and dermal delivery.

There are many literature reviews related to the electrospinning process as

Ding et al. [3] prepared nanoscale PVA fiber (100-500 nm) aggregates with an

electrospinning technique. Electrospinning conditions, including the concentration (10 wt%), tip-to-collector distance (TCD) (8 cm) and voltage (19 kV), were used to obtain thinner and regular PVA fibers. With increasing the concentration of PVA solution, the larger fiber diameter was observed. Moreover, a chemical crosslinking method was used to crosslink the nanoscale PVA fiber aggregates. The average diameter of the fibers was about 280 nm when the small amount of glyoxal was added to the PVA solution. The water uptake decreased with the increasing weight percentage of glyoxal to PVA. And the tensile strength of the PVA fiber aggregates increased when more weight percentage of glyoxal was added, indicating the crosslinked PVA fiber aggregates had better antiwater solubility and mechanical properties than the noncrosslinked PVA fiber aggregates.

Kamonrat et al. [4] prepared ultrafine fibers of PVA and PVA-alginate blend

by electrospinning technique. Effect of process parameters, i.e. applied voltage, gap distance between electrodes, and solution parameter, i.e. polymer concentration, on size and shape of fiber and ability of fiber formation were investigated. For PVA system, fiber size decreased as applied voltage and distance were increased. PVA and PVA-alginate solution were loaded with 0.10, 0.15, 0.20 and 0.25 g of tetracycline hydrochloride were electrospun into fibers with applied voltage and gap distance of 8 kV and 10 cm. Releasing behavior of tetracylcine hydrochloride in drug loaded fibers was studied in acetate buffer at pH 5.5, 37oC for 24 hours. The different from PVA and alginate blended coated on PVA with tetracycline hydrochloride fiber was studied. it was found that PVA with tetracycline hydrochloride fiber gave 86.50% and PVA and alginate blended coated on PVA with tetracycline hydrochloride fiber gave 44% for 24 hours.

Siriorn et al. [5] prepared polycaprolactone fibers and polycaprolactone fibers

mixed diclofenac sodium by electrospinning process for wound dressing application. Effect of solvent, polymer concentration, applied voltage and gap distance between electrodes on morphology and size of fiber and fiber formation ability were studied. The most uniform fibers, in term of shape and size, were obtained from 15% (w/v) of PCL in methylene chloride solution with a gap distance of 15 cm at 7.5 kV. Using this condition, 10 ml of PCL solutions were loaded with. 0.01, 0.03, 0.05 and 0.07 g of diclofenac sodium (DS) were electrospun into fibers, Releasing behavior of DS from these fibers in acetate buffer at pH 5.5 and 37oC were follow by UV-visible spectrophotometry. After 48 hours, the amount of DS released from fibers with the DS loading of 0.01, 0.03, 0.05 and 0.07 g were 60%, 48%, 46% and 30%, respectively.

Duan et al. [6] discovered that ultrafine fibers could not be electrospun from

chitosan solution in aqueous acetic acid, but formed after addition of poly (ethylene oxide) (PEO) in an aqueous solution of 2 wt% acetic acid in 2:1 or 1:1 mass ratios of chitosan to PEO from 4-6 wt% chitosan/PEO solutions at 15 kV voltage, 20 cm capillary-collector distance and flow rate 0.1 ml/h. With the addition of PEO, the conductivities of chitosan/PEO solutions decreased in comparison with the same concentration of the chitosan solution. The surface tension of PEO solutions varied with the molecular mass of PEO reduced slightly with increasing the concentration of

PEO solutions. The surface tensions of chitosan/PEO solutions with different molecular masses of PEO were similar to those of PEO solutions at the same concentration. The viscosity clearly increased with enhancing the concentration of both chitosan solutions and PEO solutions. With increasing the molecular mass of PEO, the viscosities of blended chitosan/PEO solutions increased. During the electrospinning process of the chitosan/PEO solutions, the ultrafine fibers were obtained with diameters from 80 nm to 180 nm, while microfibers with thicker diameters were also generated. The morphology of the ultrafine fibers electrospun from chitosan/PEO solutions was influenced strongly by the solution concentration and the mass ratio of chitosan to PEO, whereas the molecular mass of PEO had little effect on it. Microfibers mainly contained PEO, while ultrafine fibers consisted of chitosan due to the phase separation of the chitosan/PEO solutions during the electrospinning process.

Ohkawa et al. [7] discovered that chitosan in formic acid (FA) could not be

electrospun, but formed when a small portion of the PVA was added. Homogenous fibers from chitosan and PVA solutions were obtained as the ratio of the chitosan to PVA at 50:50 with an average diameter of 120 nm. With increasing the volumes of PVA, the fibers were thicker. However, chitosan fibers were generated when trifluoroacetic acid (TFA) was used as the solvent. An homogenous network of the electrospun chitosan fibers was observed at the concentration of 8 wt% with an average diameter of 490 nm. In order that the preparation of a homogenous (not interconnected) fiber network of chitosan, dichloromethane (MC) was mixed with TFA as the solvent for chitosan. Homogenous chitosan fibers were obtained at a TFA: MC ratio of 70:30 as the solvent with an average diameter of 330 nm.

Zhang et al. [8] produced submicron poly (vinyl alcohol) (PVA) fiber mats by

electrospinning of aqueous PVA solutions. There was a slightly increase in an average fiber diameter with increasing applied electric voltage. Tip-target distance had no significant effects on fiber morphology; however the morphology was slightly changed by the flow rate. With increasing the concentration of PVA solution, the morphology was changed from beaded fiber to uniform fiber structure and the fiber diameter was also increased from 87±14 nm to 246±50 nm. PVA fiber diameters were gradually decreased from 214±19 nm to 159±21 nm with increasing amount of NaCl. The morphology of electrospun PVA changed from the ribbon-like fibers to uniform fibers and then to beaded fibers when the hydrolysis degree (DH) of PVA was increased from 80% to 99%.

Son et al. [9] found that 7 wt% PVA solutions were electrospun at 19 kV

positive voltage, 10 cm working distance, and 1 ml/h solution flow rate. In order to investigate the effect of pH on the morphology and diameter of electrospun PVA, PVA solutions were electrospun at various pH values from 2.0 to 12.9. The conductivity of PVA solutions was strongly depended on pH that PVA fibers with much smaller diameter can be obtained at low and high pH values, while their viscosity and surface tension were not significantly affected by pH. Moreover, with increasing the conductivity, the average diameter of PVA fiber was decreased. The average diameter of PVA fibers electrospun at pH 7.2 was 290 nm. Electrospun PVA fibers became straighter and finer with increasing pH under basic conditions, whereas the electrospinning of PVA solution was not continuous and PVA fibers with beads-

on-string structures were obtained due to the protonation of PVA under acidic conditions.

Geng et al. [10] prepared chitosan electrospun fibers from aqueous chitosan

solution using concentrated acetic acid solution as a solvent. A uniform nanofibrous

mat of average fiber diameter of 130 nm was obtained from the following optimum

condition: 7%chitosan solution in aqueous 90% acetic acid solution was successfully

electrospun in the electric field of 4kV/cm. The acetic acid concentration was the

most important parameter in the electrospinning, which decreased surface tension of

the chitosan solution and at the same time increased charge density of jet without

significant effect on viscosity. Only chitosan solution of a molecular weight of

106,000g/mol produced bead-free and more uniform electrospun fiber. The average

diameter decreased with narrow diameter distribution as applied electric field

increased.

2.2 Biopolymers

2.2.1 Chitin/Chitosan

Chitin is a polysaccharide in nature. Chitin is found in the exoskeleton of

crustacean, insects, annelids, mollusks, and some fungi.

Chitin is composed of 2-acetamido-2-deoxy-β-D-glucopyranose residues

(N-acetyl-D-glucosamine residues), linked by (1 4)-linkages.

The chemical structure of chitin is shown in FIGURE 2-2.

FIGURE 2-2 Chemical structure of chitin

(Garner and Blackwell, 1975) proposed that chitin is predominantly present as a

fibrillar crystalline material. Based on infrared spectroscopy and x-ray diffraction data, chitin can be found in one of the three crystalline forms: α-chitin, β-chitin and γ-chitin, respectively. The molecules in orthorhombic α-chitin are arranged very tightly in an anti-parallel fashion. α-chitin is mainly present in shells of crabs, lobsters and shrimps. β-chitin, obtained from squid pens, takes the monoclinic form in which the chains are arranged in a parallel fashion, while γ-chitin is the form in which the molecules are arranged in both parallel and anti-parallel manner. As a result of the molecular packing, intermolecular interactions in β-chitin are weaker than those in

α-chitin, making β-chitin being more susceptible to dissolution in a number of solvents. This results in β-chitin being more reactive and versatile. Chitin is insoluble in most common organic solvents, a direct result of the strong intra- and inter-molecular hydrogen bonding.

Chitosan is a partially deacetylated polymer of acetyl glucosamine obtained

after alkaline deacetylation of the chitin. The chitosan is composed of 2-amino-2-deoxy-β-D-glucopyranose (D-glucosamine) and N-acetyl-D-glucosamine residues. The chemical structure of chitosan is represented in FIGURE 2-3.

FIGURE 2-3 Chemical structure of chitosan

Chitosan is semi-crystalline and the degree of crystallinity is a function of the

degree of deacetylation. Chitosan is insoluble at neutral and alkaline pH, but formed water-soluble salts with inorganic and organic acids including glutamic, hydrochloric, lactic and acetic acids. In acidic medium, the amine groups of the polymer are protonated resulting in a soluble, positively charged polysaccharide that has a high charge density (one charge for each D-glucosamine unit).The chitosan is a natural, nontoxic, biodegradable polysaccharide available as solution, flake, fine powder, bead, and fiber. Due to the chitosan has a large molecular weight, exhibits a positive charge, and demonstrates film-forming ability and gelation characteristics. Thus, it has been extensively used in the industry as a flocculant in the clarification of wastewater and as a chelating agent for harmful metals for the detoxification of hazardous waste. In addition, the chitosan has been exploited in the cosmetic industry, in the dental industry, for hair care products, and for ophthalmic applications, such as contact lens coating or the contact lens material. Also, it has been used as a biomaterial in veterinary applications, such as wound healing agent, antimicrobial agent, bandage material, skin grafting template, hemostatic agent and drug delivery vehicle.

The antibacterial and antifungal activities of chitosan have been followed with

great interest. Chitosan inhibits the growth of a wide variety of bacteria, fungi and etc as shown in TABLE 2-2.

TABLE 2-2 Antimicrobial chitosan

Escherichia coli

Botrytis cinerea

Proteus vulgaris

aureus (S.aureus)

Shigella dysenteriae stolonifer

Rhodotorula rubra

parahaemolyticus

hydrophila CCRC 13881

Begin and Calsteren [11] found that antimicrobial films were prepared by

dissolving chitosan into hydrochloric, formic, acetic, lactic and citric acid solutions. Chloride and citrate produced solutions with much lower viscosities than formate, acetate and lactate. Films prepared from these solutions were evaluated in tension for Young's modulus, stress and elongation at yield and break points. Films made from hydrochloric, formic and acetic acids were hard and brittle, whereas those from lactic and citric acids were soft. These results indicate that soft films produced from lactic and citric acids should be used in multilayer films or for coating. While, chloride and formate form hard films which may be used as biodegradable packaging or as support to films containing antimicrobial agents.

The mechanism of the antimicrobial activity of chitosan can be summarized as

1. The cationic nature of chitosan causes it to bind with sialic acid in

phospholipids, consequently restraining the movement of microbiological substances.

2. Oligomeric chitosan penetrates into the cells of microorganisms and prevents

the growth of cells by preventing the transformation of DNA into RNA [12].

Zheng and Zhu [13] studied in the antimicrobial activity of chitosan of different

molecular weights (MW) to E.coli and Staphylococcus aureus. The effect of the concentration and MW of chitosan were investigated. With increasing of chitosan concentration, the antimicrobial effect strengthened. Also, the concentration of chitosan reached 1.0%, the inhibition rate reached 100% for both E.coli and S.aureus. For chitosan with MW below 300kDa, the antimicrobial effect on S.aureus (a gram-positive bacteria) was strengthened as the MW increased, while the effect on E.coli (a gram-negative bacteria) was weakened; as a result of the mechanisms of the antimicrobial activity of chitosan were different between gram-positive and negative bacteria. The two antimicrobial mechanisms can be discussed in the following. For S.aureus, the antimicrobial effect was enhanced when the MW of chitosan increased because of the chitosan of higher MW forms a film which inhibits nutrient adsorptions of a positive bacteria cell. In contrast, for E.coli, the antimicrobial effect was enhanced when the MW of chitosan decreased; as a result of the chitosan of lower MW enters the microbial cell more easily and also, chitosan can adsorb the electronegative substance in the cell and flocculate them and then disturbed the metabolism of the cell.

Srinivasa et al [14] prepared chitosan/PVA blend films by wet casting method.

Moreover, blend films were characterized for optical and mechanical properties. With decreasing the chitosan concentration, the degree of transparency of films had the higher values. The tensile strength of blend films decreased with increase in PVA concentration, while %elongation of blend films declined with increase in chitosan concentration. A blend ratio of 80/20 was found to be the best.

2.2.2 Poly(vinyl alcohol) (PVA)

Poly(vinyl alcohol) is a water-soluble polymer produced industrially by

hydrolysis of poly(vinyl acetate) in the following equation below:

FIGURE 2-4 Hydrolysis of poly(vinyl acetate)

A number of grades of PVA are commercially available, which can be divided

into two types: the fully hydrolyzed and the partially hydrolyzed PVA depending on the amount of acetate groups left in the backbone (Mark and Gayload, 1980). PVA is highly biocompatible and is non-toxic, also it has high water permeability. The chemical stability of PVA at normal temperature along with its excellent physical and mechanical properties have led to its broadly practical applications in medical, cosmetic, food, pharmaceutical and packaging industries. PVA has been mainly used in fiber and film products such as paper coating, adhesives and colloid stabilizer. Ultrafine PVA fibers produced by electrospinning may have potential applications in filtration and biomedical engineering. Moreover, PVA-containing solutions have been processed by numerous techniques including sol-gel processing, phase separation and freeze-thaw cyclic treatments to produce a variety of structures [15].

2.2.3 Polyglycolide (PGA) [15]

Polyglycolide is the simplest linear aliphatic polyester. PGA was used to

develop the first totally synthetic absorbable suture, marketed as Dexon in the 1960s by Davis and Geck, Inc. (Danbury, CT). Glycolide monomer is synthesized from the dimerization of glycolic acid. Ring-opening polymerization yields high-molecular-weight materials, with approximately 1-3% residual monomer present. PGA is highly crystalline (45-55%), with a high melting point (220-225°C) and a glass-transition temperature of 35-40°C. Because of its high degree of crystallization, it is not soluble in most organic solvents; the exceptions are highly fluorinated organics such as hexafluoroisopropanol. Fibers from PGA exhibit high strength and modulus and are too stiff to be used as sutures except in the form of braided material. Sutures of PGA lose about 50% of their strength after 2 weeks and 100% at 4 weeks, and are completely absorbed in 4-6 months. Glycolide has been copolymerized with other monomers to reduce the stiffness of the resulting fibers.

2.2.4 Polylactide (PLA) [15]

Lactide is the cyclic dimer of lactic acid that exists as two optical isomers, d and

l. l-lactide is the naturally occurring isomer, and dl-lactide is the synthetic blend of d-lactide and l-lactide. The homopolymer of l-lactide (LPLA) is a semicrystalline polymer. These types of materials exhibit high tensile strength and low elongation, and consequently have a high modulus that makes them more suitable for load-bearing applications such as in orthopedic fixation and sutures. Poly(dl-lactide) (DLPLA) is an amorphous polymer exhibiting a random distribution of both isomeric forms of lactic acid, and accordingly is unable to arrange into an organized crystalline structure. This material has lower tensile strength, higher elongation, and a much more rapid degradation time, making it more attractive as a drug delivery system. Poly(l-lactide) is about 37% crystalline, with a melting point of 175-178°C and a glass-transition temperature of 60-65°C. The degradation time of LPLA is much slower than that of DLPLA, requiring more than 2 years to be completely absorbed. Copolymers of l-lactide and dl-lactide have been prepared to disrupt the crystallinity of l-lactide and accelerate the degradation process.

2.2.5 Poly (lactide-co-glycolide) [15]

Using the polyglycolide and poly(l-lactide) properties as a starting point, it is

possible to copolymerize the two monomers to extend the range of homopolymer

properties (see FIGURE 2-5). Copolymers of glycolide with both l-lactide and dl-

lactide have been developed for both device and drug delivery applications. It is

important to note that there is not a linear relationship between the copolymer

composition and the mechanical and degradation properties of the materials. For

example, a copolymer of 50% glycolide and 50% dl-lactide degrades faster than either

homopolymer. Copolymers of l-lactide with 25-70% glycolide are amorphous due to

the disruption of the regularity of the polymer chain by the other monomer. A

copolymer of 90% glycolide and 10% l-lactide was developed by Ethicon as an

absorbable suture material under the trade name "Vicryl." It absorbs within 3-4

months but has a slightly longer strength-retention time.

HO ( C CH O)m (C CH2O )n H

FIGURE 2-5 Chemical structure of poly(lactide-co-glycolide)

2.2.6 Poly(ε-caprolactone) [15]

The ring-opening polymerization of ε-caprolactone yields a semicrystalline

polymer with a melting point of 59-64°C and a glass-transition temperature of -60°C (see FIGURE 2-6). The polymer has been regarded as tissue compatible and used as a biodegradable suture in Europe. Because the homopolymer has a degradation time on the order of 2 years, copolymers have been synthesized to accelerate the rate of bioabsorption. For example, copolymers of ε-caprolactone with dl-lactide have yielded materials with more-rapid degradation rates.

HO [ (CH2)5 C O ]n CH2CH2 [ O C (CH2)5 ]n OH

FIGURE 2-6 Chemical structure of poly(ε-caprolactone)

2.3 Microbiology

2.3.1 Escherichia coli bacteria [16]

Escherichia coli (usually abbreviated to E.coli), as shown in FIGURE 2-7, is one

of the main species of bacteria that live in the lower intestines of warm-blooded animals (including birds and mammals) and are necessary for the proper digestion of food. Its presence in groundwater is a common indicator of fecal contamination. The name comes from its discoverer, Theodor Escherich. It belongs among the Enterobacteriaceae, and is commonly used as a model organism for bacteria in general.

FIGURE 2-7 The morphology of Escherichia coli at x10,000 magnification [17]

The number of individual E.coli bacteria in the feces that one human passes in

one day averages 1011 to 1013 cells. All the different kinds of fecal coli bacteria and all the very similar bacteria that live in the ground ( in soil or decaying plants, of which the most common is Enterobacter aerogenes) are grouped together under the name "coliform" (meaning "like coli" bacteria. Technically, the "coliform group" is defined to be all the aerobic and facultative anaerobic, non-spore-forming, Gram-negative, rod-shaped bacteria that ferment lactose with the production of gases such as carbondioxide and hydrogen gas and also organic acids within 48 hours at 35°C.

In the fields of water purification and sewage treatment, E.coli was chosen very

early in the development of the technology as an "indicator"of the pollution level of water, meaning the amount of human fecal matter in it, measured using the Coliform index. The main reasons for using E.coli are that there are a lot more coliforms in human feces than there are pathogens (such as Salmonella typhi, which causes typhoid).

Although E.coli is generally nonpathogenic, there are three situations that it can

cause illness as follows:

1. When the bacteria get out of the intestinal tract and into the urinary tract, they

can cause an infection sometimes referred to as "honeymoon cystitis" because intercourse can lead to introduction of bacteria into the bladder. Although it is more common in females, urinary tract infection is seen in both males and females. It is found in roughly equal proportions in elderly men and women. Since bacteria invariably enter the urinary tract through the urethra, poor toilet hygiene can

predispose to infection but other factors are also important (pregnancy in women, prostate enlargement in men) and in many cases the initiating event is unclear.

2. When the bacteria get out of the intestinal tract through a perforation (a hole

or tear, which could be caused by an ulcer) and into the abdomen, they usually cause an infection called "peritonitis" that can be fatal. However, E.coli are extremely sensitive to antibiotics such as streptomycin, so treatment with antibiotics is usually effective.

3. Certain strains of E.coli are toxigenic (some produce a toxin very similar to

that seen in dysentery) and can cause food poisoning usually associated with eating contaminated meat and lead to diarrhea. A particularly virulent example of such a strain of E.coli is E.coli O157:H7.

2.3.2 The requirements for microbial growth [18,19]

The requirements for microbial growth can be divided into two main categories:

physical and chemical.

2.3.2.1 Physical requirements include temperature, pH and osmotic

2.3.2.1.1 Temperature

At low temperature a temperature rise increases the growth rate because the

velocity of an enzyme-catalysed reaction, like that of any chemical reaction, will roughly double for every 10°C rise in temperature. Because the rate of each reaction increases, metabolism as a whole is more active at higher temperatures, and the microorganism grows faster. Beyond a certain point further increases actually slow growth, and sufficiently high temperatures are lethal. High temperatures damage microorganisms by denaturing enzymes, transport carriers, and other proteins. Microbial membranes are also disrupted by temperature extremes; the lipid bilayer simply melts and disintegrates. Although functional enzymes operate more rapidly at higher temperatures, the microorganism may be damaged to such an extent that growth is inhibited because the damage can not be repaired. At very low temperatures, membranes solidify and enzymes do not work rapidly. The effect of temperature on growth rate as shown in FIGURE 2-8.

FIGURE 2-8 The effect of temperature on growth rate [18]

Most microorganisms grow well at the temperatures favored by humans. Most

bacteria grow only within a limited range of temperatures, and their maximum and minimum growth temperatures are only about 30°C apart. They grow poorly at the high and low temperature extremes within their range. TABLE 2-3 represents the temperature for growth of bacterium.

TABLE 2-3 Minimum, maximum and optimum temperature for growth of certain

bacteria and archaea. [20]

Temperature for growth (ºC)

monocytogenes Vibrio marinus

maltophilia Thiobacillus

novellus Staphylococcus

aureus Escherichia coli

kluyveri Streptococcus

pyogenes Streptococcus

pneumoniae Bacillus

hermuslavo Thermus aquaticus

jannaschii Suulfolobus

acidocaldarius Pyrobacterium

Microorganisms are classified into three primary groups on the basis of their

preferred range of temperature as follow: psychrophiles (cold-loving microbes), mesophiles (moderate-temperature-loving microbes), and thermophiles (heat-loving microbes).

FIGURE 2-9 and TABLE 2-4 represent organisms in relation to temperature

requirements for growth.

FIGURE 2-9 Growth rate versus temperature for five environmental classes of

procaryotes.

Most procaryotes will grow over a temperature range of about 30 degrees. The

curves exhibit three cardinal points: minimum, optimum and maximum temperatures

for growth. There is a steady increase in growth rate between the minimum and

optimum temperatures, but slightly past the optimum a critical thermolabile cellular

event occurs, and the growth rates plunge rapidly as the maximum T is approached.

As expected and as predicted by T.D. Brock, life on earth, with regard to temperature,

exists wherever water remains in a liquid state. Thus, psychrophiles grow in solution

wherever water is supercooled below 0 degrees; and extreme thermophilic archaea

(hyperthermophiles) have been identified growing near deep-sea thermal vents at

temperatures up to 120 degrees. Theoretically, the bar can be pushed to even higher

temperatures. [20]

TABLE 2-4 Terms used to describe organisms in relation to temperature

requirements for growth. [20]

Temperature for growth (°C)

Below 20 Grow best at relatively low T

Above 25 Able to grow at low T but

prefer moderate T

Below 45 Most bacteria esp. those living

in association with warm- blooded animals

Among all thermophiles is

wide variation in optimum and maximum T

Microorganisms which grow at an optimum pH well below neutrality (7.0) are

called acidophiles. Those which grow best at neutral pH are called neutrophiles and those that grow best under alkaline conditions are called alkaliphiles. Most bacteria grow best in a narrow pH range near neutrality, between pH 6.5 and 7.5. Very few bacteria grow at an acidic pH below about pH 4. Some bacteria, called acidophiles, are remarkably tolerant of acidity. For example, one type of chemoautotropic bacteria, which is found in the drainage water from coal mines and oxidizes sulfur to form sulfuric acid can survive at a pH value of 1.

The range of pH over which an organism grows is defined by three cardinal

points: the minimum pH, below which the organism cannot grow, the maximum pH, above which the organism cannot grow, and the optimum pH, at which the organism grows best. For most bacteria there is an orderly increase in growth rate between the minimum and the optimum and a corresponding orderly decrease in growth rate between the optimum and the maximum pH, reflecting the general effect of changing [H+] on the rates of enzymatic reaction as shown in FIGURE 2-10.

FIGURE 2-10 Growth rate versus pH for three environmental classes

of procaryotes.

When bacteria are cultured in the laboratory, they of ten produce acids that

eventually interfere with their own growth. To neutralize the acids and maintain the proper pH, chemical buffers are included in the growth medium. The peptones and amino acids in some media act as buffers, and many media also maintain phosphate salts. Phosphate salts have the advantage of exhibiting their buffering effect in the pH growth range of most bacteria. They are nontoxic and also provide phosphorus, essential nutrient.

2.3.2.1.3 Osmotic pressure

Microorganisms obtain almost all their nutrients in solution from the

surrounding water. Thus, they require water for growth and are made up of 80-90% water. High osmotic pressures have the effect of removing necessary water from a cell. When a microbial cell is in a solution that a higher concentration of solutes than in the cell (hypertonic), the cellular water passes out through the plasma membrane to the high solute concentration. This osmotic loss of water causes plasmolysis, or shrinkage of the cell's cytoplasm. It is shown in FIGURE 2-11.

The increased osmotic pressure can inhibit the growth of some bacteria. If the

osmotic pressure is unusually low (hypotonic) such as in distilled water, water tends to enter the cell rather than leave it. Some microbes that have a relatively weak cell wall may be lysed by such treatment.

FIGURE 2-11 Plasmolysis [19]

(A) Normal cell in isotonic solution. Under these conditions, the osmotic pressure in

the cell is equivalent to a solute concentration of 0.85% sodium chloride (NaCl).

(B) Plasmolyzed cell in hypertonic solution. If the concentration of solutes such as

NaCl is higher in the surrounding medium than in the cell (hypertonic), Water tends to leave the cell. Growth of the cell is inhibited.

2.3.2.2 Chemical requirements include sources of carbon, nitrogen,

sulfur, phosphorus, trace elements, oxygen, and organic growth factors.

Every organism must find in its environment all of the substances required for

energy generation and cellular biosynthesis. The chemicals and elements of this environment that are utilized for bacterial growth are referred to as nutrients or nutritional requirements. In the laboratory, bacteria are grown in culture media which are designed to provide all the essential nutrients in solution for bacterial growth.

2.3.2.2.1 The major elements

At an elementary level, the nutritional requirements of a bacterium such as E.

coli are revealed by the cell's elemental composition, which consists of C, H, O, N, S. P, K, Mg, Fe, Ca, Mn, and traces of Zn, Co, Cu, and Mo. These elements are found in

the form of water, inorganic ions, small molecules, and macromolecules which serve

either a structural or functional role in the cells. The general physiological functions

of the elements are outlined in TABLE 2-5.

TABLE 2-5 Major elements, their sources and functions in bacterial cells [20]

Main constituent of cellular material

compounds or CO2

Constituent of cell material and cell

water; O2 is electron acceptor in

aerobic respiration

Constituent of amino acids, nucleic

acids nucleotides, and coenzymes

Main constituent of organic

compounds and cell water

Constituent of nucleic acids,

nucleotides, phospholipids, LPS,

Constituent of cysteine, methionine,

glutathione, several coenzymes

Main cellular inorganic cation and cofactor for certain enzymes

Inorganic cellular cation, cofactor for

certain enzymatic reactions

Inorganic cellular cation, cofactor for certain enzymes and a component of endospores

Component of cytochromes and certain nonheme iron-proteins and a cofactor for some enzymatic reactions

2.3.2.2.2 Trace elements

Trace elements are metal ions required by certain cells in such small amounts that it is difficult to detect (measure) them, and it is not necessary to add them to culture media as nutrients. Trace elements are required in such small amounts that they are present as "contaminants" of the water or other media components. As metal ions, the trace elements usually act as cofactors for essential enzymatic reactions in the cell. One organism's trace element may be another's required element and vice-versa, but the usual cations that qualify as trace elements in bacterial nutrition are Mn, Co, Zn, Cu, and Mo.

2.3.2.2.3 Vitamins

Some vitamins that are frequently required by certain bacteria as growth factors

are listed in TABLE 2-6.

TABLE 2-6 Common vitamins required in the nutrition of certain bacteria [20]

Precursor for the biosynthesis of

Tetrahydrofolate

Transfer of one-carbon units and required for synthesis of thymine, purine bases, serine, methionine and pantothenate

Biosynthetic reactions that require CO2 fixation

Transfer of acyl groups in oxidation of keto acids

CH4 production by methanogens

sulfonic acid Nicotinic acid

NAD (nicotinamide

Electron carrier in

adenine dinucleotide)

dehydrogenation reactions

Pantothenic acid

Coenzyme A and the

Oxidation of keto acids and acyl

Acyl Carrier Protein

group carriers in metabolism

Pyridoxal phosphate

Transamination, deamination, decarboxylation and racemation of amino acids

Oxidoreduction reactions

mononucleotide) and FAD (flavin adenine dinucleotide)

Thiamine pyrophosphate

Decarboxylation of keto acids and

transaminase reactions

Cobalamine coupled to

Transfer of methyl groups

adenine nucleoside

Electron transport processes

2.3.2.2.4 Oxygen

Oxygen is a universal component of cells and is always provided in large

amounts by H2O. However, procaryotes display a wide range of responses to

molecular O2 (TABLE 2-7)

TABLE 2-7 Terms used to describe O2 relations of microorganisms [20]

Required (utilized for aerobic respiration)

Required but at levels

Obligate Anaerobe

Not required for

growth but utilized

Aerobe) Aerotolerant

Not required and not

Obligate aerobes require O2 for growth; they use O2 as a final electron acceptor in aerobic respiration. Obligate anaerobes (occasionally called aerophobes) do not need or use O2 as a nutrient. In fact, O2 is a toxic substance, which either kills or inhibits their growth. Obligate anaerobic procaryotes may live by fermentation, anaerobic respiration, bacterial photosynthesis, or the novel process of metanogenesis. Facultative anaerobes (or facultative aerobes) are organisms that can switch between aerobic and anaerobic types of metabolism. Under anaerobic conditions (no O2) they grow by fermentation or anaerobic respiration, but in the presence of O2 they switch to aerobic respiration. Aerotolerant anaerobes are bacteria with an exclusively anaerobic (fermentative) type of metabolism but they are insensitive to the presence of O2. They live by fermentation alone whether or not O2 is present in their environment.

2.3.3 Culture Media for the Growth of Bacteria

For any bacterium to be propagated for any purpose it is necessary to provide

the appropriate biochemical and biophysical environment. The biochemical (nutritional) environment is made available as a culture medium, and depending upon the special needs of particular bacteria a large variety and types of culture media have been developed with different purposes and uses. Culture media are employed in the isolation and maintenance of pure cultures of bacteria and are also used for identification of bacteria according to their biochemical and physiological properties.

The manner in which bacteria are cultivated, and the purpose of culture media,

varies widely. Liquid media are used for growth of pure batch cultures, while

solidified media are used widely for the isolation of pure cultures, for estimating viable bacterial populations, and a variety of other purposes. The usual gelling agent for solid or semisolid medium is agar, a hydrocolloid derived from red algae. Agar is used because of its unique physical properties (it melts at 100 degrees and remains liquid until cooled to 40 degrees, the temperature at which it gels) and because it cannot be metabolized by most bacteria. Hence as a medium component it is relatively inert; it simply holds (gels) nutrients that are in aqueous solution. 2.3.4 The growth curve The growth of microorganism reproducing by binary fission can be plotted as the logarithm of the number of viable cells versus the incubation time the resulting curve has four distinct phases as FIGURE 2-12 shown.

FIGURE 2-12 Microbial growth curve

2.3.4.1 Lag phase

When microorganisms are introduced into fresh culture medium, usually no

immediate increase in cell number occurs, and therefore this period is called the lag phase. Although cell division does not take place right away and there is no net increase in mass, the cell is synthesizing new components. Inoculation of a culture into a chemically different medium also results in a longer lag phases. On the other hand, when a young, vigorously growing exponential phase culture is transferred to fresh medium of the same composition, the lag phase will be short or absent. 2.3.4.2 Log phase

Microorganisms are growing and dividing at constant rate of growth during the

exponential phase. The population will double in number during a specific length of time called the generation time or doubling time. Due to the population is doubling every generation, the increase in population is always 2n where n is the number of generations. The resulting population increase is exponential or logarithmic. Cellular reproduction is most action during this period, and generation time reaches a constant minimum. Because the generation time is constant, a logarithmic plot of growth during the log phase is a straight line. 2.3.4.3 Stationary phase

During stationary phase, population growth ceases and the growth curve

becomes horizontal. The total number of viable microorganisms remains constant

This may result from a balance between cell division and cell death. Moreover, if an essential nutrient is severely depleted, population growth will slow. Also, population growth may cease due to the accumulation of toxic waste products. 2.3.4.4 Death phase

The number of deaths eventually exceeds the number of new cells forms, and

the population enters the death phase or logarithmic decline phase. This phase

continues until the population is diminished to a tiny fraction of the number of cells in

the previous phase, or the population dies out entires.

2.4 Wound healing and wound dressing

The skin is subject to various insults and injuries. Cells on the surface of the

skin are constantly being replaced by regeneration from below with the top layers sloughing off. The repair of an epithelial wound is merely a scaling up of this normal process. An abrasion occurs when a physical force removes epidermal cells to different degrees over the area of the injury. The margins are usually superficial while the interior of the abrasion may extend into the dermis. Initially the wound is filled by blood colt and decaying tissue that later dries out to become a scab.

In a burn, the dead epidermis may remain on the wound and may even be

elevated by the collection of serum between layers of the epidermis thus forming a blister. Burns can be caused by heat, cold, chemicals or ultraviolet light. Blisters are also formed by friction.

A puncture wound is made by a sharp pointed instrument and is usually

collapsed. This type of wound is an ideal site for an infection to begin. 2.4.2 Healing

Inflammation is the normal acute reaction of the tissues after any injury. The

immediate response of the blood supply to the area is a nervous constriction of the vessels. This is followed immediately by vasodilation that allows fluid to exit the capillaries and flood the area. The fluid, plasma, contains fibrinogen which is cleaved to form fibrin strands that form substantial portions of the blood clot. Chemicals in the plasma and on injured tissues attract white blood cells (macrophages and neutrophils) that enter the area and start to clean up foreign material, bacteria and dead cells. Accumulation of a large number of white blood cells leads to pus in the wound. Eventually the clot is replaced by granulation tissue, a connective tissue with a rich blood supply. Collagen and ground substance (proteoglycans) are produced by the fibroblasts within the granulation tissue. The scar is red because of the ample blood supply. The color fades to white as the vascularization decreases and the collagen matrix matures. Myofibroblasts in the wound area are responsible for wound contraction; the normal process where the edges of the wound migrate toward the wound center. Epithelial cells divide and migrate over the basal layers to regenerate the epithelium. Basal cells continue to divide until the epithelial stratification is restored. When the coverage of the wound surface beneath the scab is complete the scab sloughs off and the epidermis begins to keratinize. Remodeling of the collagen matrix may continue for years with the extent varying among individuals and with age. The scar is rarely as strong as the tissue it replaced. Deeper or larger skin wounds

may result in the loss of epidermal structures in that area. Hair follicles, sweat glands and melanocytes may not be replaced. 2.4.3 Treatment

Bleeding from surface wounds can usually be controlled by applying pressure

directly to the wound. The wound should be cleaned with mild soap and water and irrigated well to remove foreign debris and bacterial contaminants. If the edges of a deep laceration are ragged, the doctor may choose to trim them to facilitate healing.

Deeper cuts or incisions require some sort of manual closure such as sutures,

staples or tapes. In relatively simple wounds, the edges may be brought in close approximation by the use of deep sutures and superficial means to minimize scar formation. Before closing a wound with an invasive method the doctor will usually anesthetize the local area with a short acting anesthetic such as lidocaine.

Suture is foreign material and can initiate an inflammatory response. Suture

material may be made of ‘cat gut', newer synthetic polyglycolic acid derivatives, nylon, silk, or stainless steel. The first two examples are absorbable and the others must be removed. Fine suture material and minimal tightening limit any additional tissue damage, inflammation and scarring. Wounds in areas that heal slower (less vascularized) or are in high stress areas require larger suture material and that the stitches be left in longer. Sometimes sutures may be removed after only a few days to minimize scarring due to the proliferation of epithelial cells along the suture tracts. A tetanus toxiod booster injection may be indicated for certain wounds dependent on the patent's immunization record.

Sterile dressings should be applied to keep a fresh wound clean. Sterile

dressings come in various sizes from simple gauze pads to adhesive bandages. If a wound is discharging fluid (serum), the dressing should be changed often to minimize bacterial growth. After drainage has stopped, there is no need for a dressing. Antibacterial ointments may be applied to limit surface bacterial growth and prevent the dressing from sticking to the wound. Topical antibiotics containing multiple antibiotics such as bacitracin, neomycin, or polymyxin B in fixed dosages offer several advantages including broad coverage for infections due to undetermined pathogens and delayed microbial resistance to any one antibiotic. Wounds may be cleansed with hydrogen peroxide several times daily before the reapplication of ointment. Good wound care will minimize the inflammatory response, speed healing and minimize scarring.

Chapter 3

3.1 Equipments

3.1.1 High Voltage Power Supply (Model UCS-30P/cm/VM)

3.1.2 DC Power Supply

3.1.3 Voltage Regulators (Model DC 301) 3.1.4 Scanning Electron Microscope: JEOL JSM-5800LV 3.1.5 Ion sputtering: Balzer model SCB040

3.1.6 Brookfield Viscometer: LVDV-II+ 3.1.7 Conductivity meter: LC116

3.1.8 Differential Scanning Calorimeter: NETZSCH DSC 200

3.1.9 Fourier-transform Infrared Spectrometer: Perkin-Elmer 1760x

3.1.10 Laminar flow: ISSCO Lamina flow model BV124, HS124 3.1.11 Incubator shaker: INNOVA 4000, 4080 3.1.12 pH meter: METTLER TOLEDO S20-K 3.1.13 Autoclave: SANYO LABO 3.1.14 Spectrophotometer: BECKMAN COULTER DU640 3.1.15 Petri dish 3.1.16 Syringe and spinneret 3.1.17 Aluminum foil 3.1.18 Desicator 3.1.19 Oven 3.1.20 Magnetic Stirrer

High-voltage power

DC Power Supply

Voltage Regulators

FIGURE 3-1 Electrospinning instrument

3.2 Chemical reagents

3.2.1 Poly(vinyl alcohol) (Analytical grade; BDH, England; MW 115,000)

3.2.2 Chitosan (Biolife (Thailand); MW 250,000)

3.2.3 2%v/v aqueous acetic acid

3.2.4 Distilled water

3.2.5 Escherichia coli DH5 (E.coli)

3.3 Experimental methods

3.3.1 Preparation of PVA/chitosan solutions

PVA/chitosan solutions with concentration of 10 wt% PVA blended with 2 wt%

and 3 wt% chitosan, respectively. PVA solution was prepared by dissolving PVA in warm water (80°C) under magnetic stirring continuously until the solution was cleared while chitosan solutions were prepared by dissolving chitosan in aqueous 2%v/v acetic acid under magnetic stirring overnight at room temperature to obtain homogeneous solutions. The weight ratios of PVA to chitosan were selected as ranging from 90/10 to 10/90, respectively. The blended PVA/chitosan solutions were stirred under magnetic stirring for a while.

3.3.2 Electrospinning

The electrospinning instrument is represented in Fig 3-1. The amount of the

polymer solution was contained in a 5-ml syringe with a metal capillary (No.18), that is, a needle with blunt filed tip. The capillary was connected with a high voltage power supply (Model UCS-30P/cm/VM), which could generated positive DC voltages. A piece of aluminum foil was placed below the capillary tip as the ground collector. The electrospun fibers were obtained at 15 kV Voltage, 10 cm collection distance.

3.3.3 Parameters of electrospinning process

3.3.3.1 Concentration of chitosan solutions

respectively were blended with 10 wt% PVA for electrospinning. The electrospun fibers were formed at 15 kV, 10 cm collection distance.

3.3.3.2 Collection distances

The weight ratios of 10 wt% PVA to 2 wt% chitosan as 50/50 and 60/40 were

selected for electrospinning and lead to studying in the effect of collection distance to the fiber diameter. The fibers were spun at 15 kV while the distances were varied ranging from 6, 8, 10 to12 cm, respectively.

3.3.3.3 Applied electrical potentials

The weight ratios of 10 wt% PVA to 2 wt% chitosan as 50/50 and 60/40 were

selected for studying in the effect of voltage to the fiber diameter. The electrospun fibers were obtained at 10 cm of collection distance but the voltages were applied as follows: 10, 13, 15, 18 and 20 kV, respectively.

3.3.4 Characterization

3.3.4.1 Viscometry

The viscosity of the blended PVA/chitosan solutions was measured in a

Brookfield Viscometer (model LVDV-II+).

3.3.4.2 Conductivity Meter

The electric conductivity of the solutions was tested in a conductivity meter

3.3.4.3 Scanning Electron Microscopy (SEM)

The morphology of the electrospun fibers of PVA/chitosan was observed under

a JEOL JSM-5800LV scanning electron microscope after gold coating by an Ion sputtering with 15 mA for 3.5 minutes each sample. The average fiber diameter and diameter distribution were obtained from the diameter of 100 fibers taken from a number of SEM micrographs which fiber diameter was measured by using SemAfore program. The diameters were presented as the average ± standard deviation. 3.3.4.4 Fourier-transform Infrared Spectroscopy (FTIR)

For the measurements of FT-IR, the samples of electrospun fibers were

prepared by electrospinning of blended PVA/chitosan solutions at 15 kV, 10 cm collection distance. FT-IR measurements were performed in a FT-IR Spectrometer 1760x (Perkin-Elmer) to verify the composition of fibers from functional groups. 3.3.4.5 Differential Scanning Calorimetry (DSC)

To investigate the melting points and the shift of endothermic peaks of

electrospun fibers, the fibers were performed in a NETZSCH DSC 200 at 10°C/min heating rate from room temperature to 250°C. The samples were stored in a desiccator prior to analysis.

3.4 Antibacterial assessment of the electrospun fibers

3.4.1 Nutrient Agar and Nutrient Broth preparation

The preparation of growth media for microorganisms requires ingredients which

supports basic growth of bacterial colonies, and must also be sterile so as not to grow environmental contaminants.

3.4.1.1 Nutrient Broth preparation

Ingredients of Nutrient Broth (NB) as follows:

Yeast extract 5 g/l

Nutrient Broth was prepared by adding all of NB ingredients to distilled water

and this mixture was agitated until the solution was clear and also adjusted pH value become 7 by pH meter. Then, this was sterilized in a steam autoclave under these conditions, steam at a pressure of about 15 pounds per square inch (121°C) in about 15 minutes. After that, this mixture was placed at room temperature for testing.

3.4.1.2 Nutrient Agar preparation

Ingredients of Nutrient Agar (NA) as follows:

Yeast extract 5 g/l

To mix all of them in distilled water become homogeneous solution and prepare

NA in the same way as NB in 3.4.1.1.

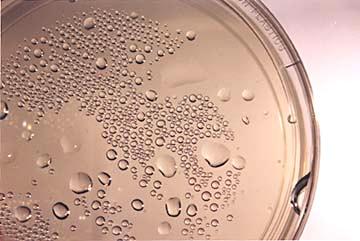

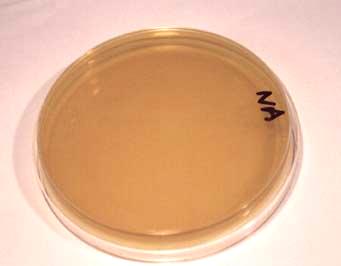

After that, sterilized NA was pour into the plate which agar media is liquid

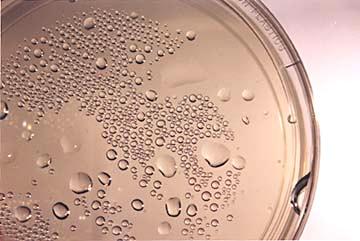

when hot while the solid when cooled (solidification occurs at approximately 45°C). If the melted media is poured too hot (above 50°C) then condensation will form inside of the plate as shown in FIGURE 3-2A. The condensation is not desirable, as it will interfere with growing isolated colonies of bacteria. A nutrient agar plate which has been poured properly at the proper temperature and with sterile technique as shown in FIGURE 3-2B. Notice there is no condensation and there is currently no growth of any kind on the agar surface.

(A) Improper plate

(B) Proper plate

FIGURE 3-2 Agar plate [21]

3.4.2 Streak plate method of isolation

The streak plate technique is essentially a method to dilute the number of

organisms, decreasing the density. This allows for individual colonies to be isolated from other colonies. Each colony is considered "pure," since theoretically, the colony began with an individual cell. Streak plate method is following below.

The inoculating loop as shown in FIGURE 3-3 was sterilized into the flame

until the metal must glow red to refer that sterilization was considered complete and then cool by touching an uninoculated portion of the surface.

FIGURE 3-3 Inoculating loop and inoculating needle [21]

To begin with inoculating the first quadrant of an agar plate. Use a light touch.

Don't penetrate or scrap the agar surface. The microbial mixture was transferred to the edge of the agar plate with an inoculating loop or swap and then streaked out over the surface in one of several patterns as shown in FIGURE 3-4.

FIGURE 3-4 Streak plate patterns [22]

At some point in the process, single cells dropped from the loop as it was

rubbed along the agar surface and developed into separate colonies and then flamed the loop again and kept the streak plate in the incubator about 37°C for one night.

3.4.3 Starter preparation and inoculation

To inoculate a single colony in Nutrient Broth (NB) as follows:

Flame the loop until the metal must glow red and then cool it. After that, pick

out the single colony in the streak plate and put it into the NB tube, then cover the lid loosely and place into the incubator shaker with 37°C, 250 rpm for one night.

After one night, NB tube that microbial grew inside, called starter, was prepared

as a microbial stock. Microbial concentration with 1% was prepared from stock and

then inoculated into the flask which was placed in the incubator shaker with 37°C, 250 rpm for one night again.

3.4.4 Antimicrobial testing

The samples which were the electrospun fibers, that is, PVA fiber,

PVA/chitosan fibers with weight ratio as 60/40 and 50/50, respectively were tested and also nylon membrane was used as to be a control reference.

All samples were sterilized under UV laminar flow before testing with

microbial on the plate.

To prepare microbial concentration with 105 Colony-Forming Unit (CFU/ml)

from inoculated flask, microbial solution was measured the optical density with the spectrophotometer at 600 nm and then calculated the volume of microbial solution to be used in order to dilute with Nutrient Broth (NB) as shown in APPENDIX F.

In the method of antimicrobial testing, begin with 3 ml of NB was filled in the

agar plate and then placed the large piece of nylon membrane on the agar as to be base for electrospun fibers to put on it. All samples, i.e. nylon membrane(control), PVA/chitosan electrospun fiber with ratio as 60/40 and 50/50, which were cut to be a size of 5x5 mm were dip into microbial solution with 105 CFU/ml and then placed them over the nylon membrane which was on the agar plate before. Whereas, PVA electrospun fibers can dissolve rapidly in liquid thus a little drop of microbial solution about 2-3 µl was dropped onto PVA fibers that place on the agar plate instead of dipping fibers into the microbial solution as described above. Lastly, this agar plate was taken into the incubator with 37°C for 4 hours.

After that, these samples were fixed with glutaraldehyde and entered the Critical

Point Drying (CPD) process in order to stop the growth of microbial and used for Electron Microscopy to observe the scanning electron micrographs in term of the morphology of E.coli cells.

Chapter 4

Results and Discussion

Results can be classified into three parts as follows: Firstly, characterization of